MAXSON AUTOMATIC MACHINERY COMPANY (Westerly RI USA) offers a feature on its precision sheeters that insures the skids of sheeted stock delivered to the printing press are free of splices that could smash blankets and cause press down time.

MAXSON AUTOMATIC MACHINERY COMPANY (Westerly RI USA) offers a feature on its precision sheeters that insures the skids of sheeted stock delivered to the printing press are free of splices that could smash blankets and cause press down time.

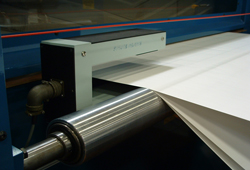

A capacitance type splice detector is mounted prior to the cutter infeed. The detector senses a change in web thickness and signals the reject gate to divert the spliced sheet at speed of up to 300 cuts per minute. The controls for the splice detector are conveniently located near the monitoring equipment. Adjustment of the detector’s sensitivity is simple and straightforward and has the added benefit of detecting a single splice within a pack of up to eight webs. When the splice detector activates the reject, a direction gate alters the flow of sheet to a Customer supplied bin. Through a drive arrangement, the slow speed tape system is stopped; positioning the last acceptable sheet cut on the slow speed tapes. This eliminates jam-ups at the overlap section when the sheet flow is resumed to the stacker, by insuring the oncoming sheet’s leading edge positively overlaps the trailing edge of the last acceptable sheet. Please contact Brent H. Burdick, Director of Sales & Marketing, for further information or your graphic requirements for the attached photographs by telephone at (401) 596-0162 or by e-mail at bburdick@maxsonautomatic.com.