The purchase of high-speed precision sheeter has helped give an Illinois-based board converter greater flexibility while satisfying the growing demand for its product and opening up market opportunities.

Jarvis Cutting Elk Grove Village, IL, was founded in 1981 to serve as the converting arm for its parent company, Andrews Paperboard. Today, the company employs 12. The majority of its customers are located in the Midwest.

As a job-lot converter, Jarvis’s product line includes folding-carton and bending-chipboard stock for use as pad interleaves and inserts for boxes.

Until two years ago, the company purchased all of its inventory in sheet form. The stock would then be trimmed to a specific order size. This approach worked well in the beginning but in time, the availability of sheets became scarce. The problem of a short supply was compounded by the fact that the converter’s business was growing.

“In this business, the more flexible you are, the better your market position, “Craig Calas, Jarvis president, said. “Rolls were easier to get than sheets so we decided to set up an in-house sheeting operation.”

The company selected a used sheeter to start the operation. Although the unit was slow and inaccurate, it gave the firm greater flexibility. Sheeting proved to a boon to the company’s business.

“At one point, we were so busy that we were forced to give our customers a week’s lead time,” Calas said. “Many of our customers with just-in-time production schedules needed stock faster.”

Within a short time, the company realized that its existing sheeter couldn’t keep up with demand.

“Our business was growing, and we needed to turn orders around more quickly,” he said. “We needed a sheeter that was faster and more accurate than our present equipment.”

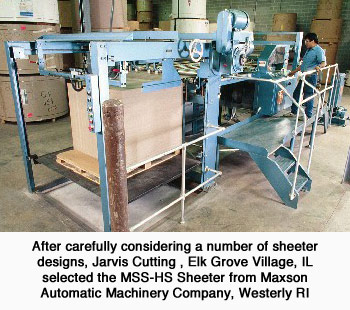

With these requirements in mind, the company selected the

MSS-HS sheeter from Maxson Automatic Machinery, Westerly, RI.

At the Illinois converting operation, the machine sheets chipboard calipers from .0009 in. to .03 in. The new sheeter operates at speeds up to 600 fpm. This represents a speed gain of more than 300 fpm over the older unit. Calas estimates the firm has seen production capacity triple with the new unit.

The added capacity means orders can be turned around faster. Lead times have shortened from one week to a couple of days. “Now we can target one-day service for our customers,” he said.

To speed setup during roll changes, the company selected a shaftless, self-loading back stand. The design of the back stand eliminates the need for an overhead hoist when loading rolls. The operator moves the roll into place while the back stand cradles the rolls and lifts it into position. A roll change can be completed in less than 5 min. compared with the 20 min. that are needed with a shaft-type design.

Accuracy also has improved with the new sheeter. The machine has a close-tolerance drive to ensure a sheet-length accuracy of

+/- 0.023 in. On the old sheeter, the converter had to oversize the sheets by 0.5 in. to compensate for any cutoff variation. The excess would then have to be guillotine trimmed.

“Now, we can sheet an order directly off a roll and send it out the door,” Calas said. Sheeting faster and more efficiently places Jarvis in a solid position to explore new markets. Opportunities for growth included first-run orders.

“With the MSS-HS, we can now sheet more consistently,” Calas said. Regarding a recent order the company sheeted for a printer, Calas said the company “didn’t get a single return. Anyone knows that in this business, if it doesn’t look good, you’ve got problems.”

“We know our niche is in the plain-chipboard market, but since buying the Maxson sheeter, we have secured orders we wouldn’t have gotten in the past,” he said. “Reputation-wise, the new sheeter has been a plus. We’ve become know more as a quality operation.”

Reprinted from Paper Film Foil Converter, November 1991