For the past 50 years, Blue Star Paper Company has been a quality supplier of sheeted paper stock. Five years ago, the company shifted its product mix to board grades. Located in

Baie d’Urfe, Quebec, Blue Star is a job lot merchant serving commercial printers and folding carton operations within the greater Montreal area.

According to the company’s president, Sam Lieblien, Blue Star’s niche lies in the ability to turn orders around quickly. While deliveries of sheeted stock from the mills can take up to 2 weeks, Blue Star can ship an order in 3 days or less. He comments, “We serve a time sensitive market. For this reason, our lead times are measured in days, not weeks.”

According to the company’s president, Sam Lieblien, Blue Star’s niche lies in the ability to turn orders around quickly. While deliveries of sheeted stock from the mills can take up to 2 weeks, Blue Star can ship an order in 3 days or less. He comments, “We serve a time sensitive market. For this reason, our lead times are measured in days, not weeks.”

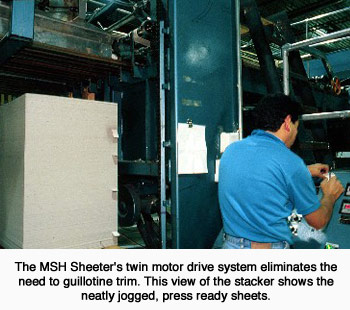

Until recently, Blue Star sheeted its board on an older sheeter and then trimmed to a finished size on a guillotine cutter. While this arrangement met the demands of the Blue Star’s sheeting requirements, Lieblien wanted something better. “We wanted to avoid guillotine trimming. A precision sheeter would eliminate this extra labor step and give us more reliability and efficiency.”

Blue Star’s product mix, customer base and emphasis on quick service meant they needed a sheeter that could handle both short and long runs efficiently. Reliability was also an important requirement. Lieblien adds, “Purchasing a precision sheeter represented a big investment relative to the size of the company. For this reason, dependability was crucial.”

After investigating several sheeter designs, Blue Star selected the MSH Sheeter from Maxson Automatic Machinery Company (Westerly, RI). The MSH Sheeter has a heavy duty cutting head, and sheets a variety of boxboard grades including SBS, TMP, screening board and CCNB.

“Even though our operators had little or no sheeter experience, there were no problems with startup. Training the operators was a breeze.” During installation, MAXSON provided a field erector to optimize the machine’s performance.

The MAXSON Sheeter features numerous equipment options, including a twin motor drive. Utilizing the latest technologies, the drive system provides square, accurate sheets. “Because the sheeted stock goes onto our customers’ high speed printing presses, squareness is very important. We have never had a complaint.”

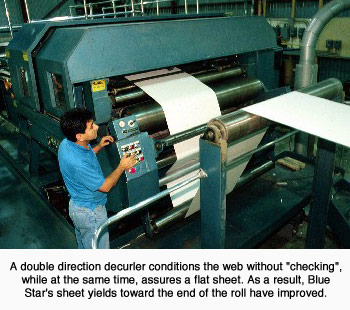

Other equipment options on the sheeter include a double direction decurl unit, an Airfoil Overlap system, and an extending grid. Of all the options, Lieblien feels that the decurl improvement. “Our sheet yields have improved towards the end of the roll. The combination of the decurl and the twin motor drive has lowered our waste by 3 percent.”

Other equipment options on the sheeter include a double direction decurl unit, an Airfoil Overlap system, and an extending grid. Of all the options, Lieblien feels that the decurl improvement. “Our sheet yields have improved towards the end of the roll. The combination of the decurl and the twin motor drive has lowered our waste by 3 percent.”

The MSH Sheeter features MAXSON’s Airfoil Overlap system, which eliminates jam-ups at the point of overlap when sheeting at high speeds. This patented device forces the tail end of the first sheet down, while forcing up the leading edge of the oncoming sheet.

Another option selected to reduce downtime was an extending grid allows for continuous operation during skid changes. The grid fingers shoot out over the pile, collecting the sheeted stock until the operator moves a new skid into position.

Lieblien is pleased with the new sheeter, noting that it has offered the company greater flexibility. “Our lead times are the same, but with the MAXSON, we now work less overtime to get the job done.” In terms of payback, Lieblien adds, “The MAXSON will meet or exceed the payback period we anticipated.”

Reprinted from The Sheeting Monitor, June 1992