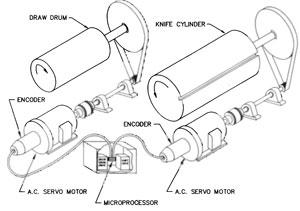

Dual Motor Drive Retrofit Allows Older Sheeters to Remain Competitive The dual motor drive retrofit from Maxson Automatic Machinery Company (Westerly, RI, USA) allows a converter’s older sheeters to remain competitive with today’s precision sheeters. This retrofit replaces a sheeter’s existing wear-prone mechanical transmission or older drive with a more reliable electrical system. This drive […]