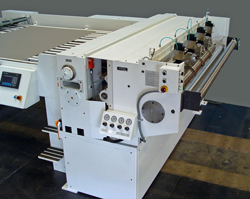

Maxson Automatic Machinery Company (Westerly RI USA) has introduced a sheeter that converts webs of multi-ply vinyl laminations into master parts which are vacuumed formed into door panels, dashboards, headliners and floor panels for the automotive industry. Using dual knife rotary cutter technology, rather than a platen die cutter design, the sheeter can convert a web up to 0.125” (3.0 mm) thick into precise shapes at speeds of up to 300 fpm (90 mpm).

Maxson Automatic Machinery Company (Westerly RI USA) has introduced a sheeter that converts webs of multi-ply vinyl laminations into master parts which are vacuumed formed into door panels, dashboards, headliners and floor panels for the automotive industry. Using dual knife rotary cutter technology, rather than a platen die cutter design, the sheeter can convert a web up to 0.125” (3.0 mm) thick into precise shapes at speeds of up to 300 fpm (90 mpm).

The dual knife/rotary cutter design has both the top and bottom blades mounted in rotating cylinders. Because of the synchronization of knife speed to web speed, no squareness adjustment is required when changing sheet lengths. The cross cutting blades are up to 75” (1905 mm) long, allowing up to an 72” (1829 mm) web trim width.

The delivery system includes an inspection conveyor that allows the Operator full view of up to 100” (254 mm) long sheets with the option to divert out of specification pieces to a reject bin. Acceptable sheets are conveyed to a stacking station that jogs the parts into neat piles.