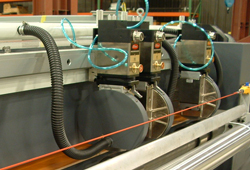

Maxson Automatic Machinery Company (Westerly RI USA) offers a vacuum system for its sheeter that removes dust at the slitters, insuring the cleanliness of sheeted stock and minimizing “hickies” (dust related defects) at the printing press. Suction is applied at the point of slitting removing any debris from the slit edge. Sheet metal bonnets enclose all but the contact edge of the top slitter blade and bottom slitter ring. Flexible hosing from each slitter is joined to a common manifold that is piped to a blower and dust collection box. The Operator’s lateral positioning of the slitters and setting the depth penetration of the upper slitters is not impeded. The slitter dust removal system is particularly effective when converting high bulk board substrates or multiple webs of coated papers, eliminating debris buildup caused by the slitting action.

Maxson Automatic Machinery Company (Westerly RI USA) offers a vacuum system for its sheeter that removes dust at the slitters, insuring the cleanliness of sheeted stock and minimizing “hickies” (dust related defects) at the printing press. Suction is applied at the point of slitting removing any debris from the slit edge. Sheet metal bonnets enclose all but the contact edge of the top slitter blade and bottom slitter ring. Flexible hosing from each slitter is joined to a common manifold that is piped to a blower and dust collection box. The Operator’s lateral positioning of the slitters and setting the depth penetration of the upper slitters is not impeded. The slitter dust removal system is particularly effective when converting high bulk board substrates or multiple webs of coated papers, eliminating debris buildup caused by the slitting action.