Hammer Lithograph’s mission statement is “Growth Through Quality,” and that is what Rochester, NY-based company has been accomplishing over the past decade. As a custom printer of sheet-fed packaging, Hammer has enjoyed annual double-digit sales increases.

Hammer’s work is varied. The company specializes in the manufacturing of high quality food and beverage labels for a customer base located nationally and internationally. It also produces over wraps for the toy, game, and retail industries, as well as specialized printing for the horticultural market.

The common bond that links Hammer’s customers together is their need for high quality, multicolor print work along with prompt service to satisfy just-in-time manufacturing schedules.

The common bond that links Hammer’s customers together is their need for high quality, multicolor print work along with prompt service to satisfy just-in-time manufacturing schedules.

Over the past seven years, Hammer’s Lithograph has invested heavily in new state-of-the-art equipment that has enabled it to operate more efficiently and has reduced operating costs. Printing equipment ranges from an eight-color, 40-in. press to several multicolor 55- and 60-in. presses. (Information regarding suppliers is proprietary.)

The next step was in-house sheeting, and Hammer was ready.

Set up to Serve

When Hammer Lithograph decided to bring sheeting in-house, the results was, in fact, not quite in-house in the literal sense of the word, but close enough. The company set up J. MacKenzie Ltd., located nearby in Rochester, as a subsidiary to supply Hammer’s printing operation with sheeted stock and also serve as a contract sheeter for other converters.

According to Steve Ray, plant manager for J. MacKenzie Ltd., “The decision to sheet in-house was driven by two factors-service and quality. As an advocate of just-in-time, we saw an advantage in sheeting from roll inventory to shorten manufacturing turnaround times. This would make Hammer Lithograph more competitive in a marketplace that is constantly demanding shorter lead times.”

“When we relied on the mills for sheeted stock, we waited a minimum of five days for material. For this service, Hammer paid a premium over the normal sheeting charges. In contrast, by bringing this operation in-house, we can have paper delivered within the hour, sheet it, and ship it to Hammer within 48 hours.”

Sheeting in-house is also viewed as a vehicle to help control the quality of raw materials, since the sheeting quality Hammer was getting from outside suppliers wasn’t as high as the company’s internal standards.

During the company’s investigation of sheeting equipment there were a number of criteria for selection. For, Ray, quality at the top of the list. “Hammer’s printing process is sheet-fed, offset in multicolor, with perfecting capabilities. Squareness and accuracy had to be on the mark. As a quality control measure, we inspect every 500 to 1,000 sheets for squareness and sheet-length accuracy. We needed a sheeter that would produce a sheet-fed skid that was press ready.”

After reviewing several designs, the company selected the MSL sheeter from Maxson Automatic Machinery Co. According to Ray, “MSL sheeter met our requirements for accuracy while at the same time offering us the flexibility to sheet a varied product mix.” Reputation, service, the location of the facility, and durability were other reasons Ray gives for the selection of Maxson.

Offering Ease of Operation

Capable of sheeting rolls up to 57 in. wide, the MSL handles a broad range of materials, including coated-one-sides, and offset paper grades in basis weights ranging from 30# to 100#. It runs solid bleached sulfate board up to .028 in. and metallized stock from 40 gsm to 40# basis weights. “The MSL allows us to sheet from board to paper and back to board without a great deal of adjustment,” says Ray.

The sheeter operates at speeds as high as 1,000 fpm, affording Hammer Lithograph the production capacity it needs to keep up with demand. “We produce about 35,000 to 40,000 lb of paper per shift, depending on size and substrate changes,” says Ray. “We can respond to rush orders faster. If any shortage problems occur when a job is on press, they can be resolved immediately. By keeping inventory on hand to a minimum, we can contain costs better.”

The sheeter operates at speeds as high as 1,000 fpm, affording Hammer Lithograph the production capacity it needs to keep up with demand. “We produce about 35,000 to 40,000 lb of paper per shift, depending on size and substrate changes,” says Ray. “We can respond to rush orders faster. If any shortage problems occur when a job is on press, they can be resolved immediately. By keeping inventory on hand to a minimum, we can contain costs better.”

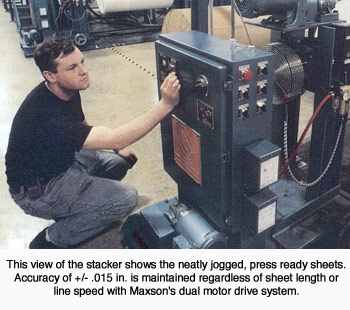

The Maxson sheeter has a dual-motor drive that provides a sheet length of +/- .015 in., regardless of cut-off length or line speed. The dual drive offers quick setup, because the sheet length is set via keypad entry. The sheeter features auto tension control and auto squareness .

“The dual motor drive is one way in which the MSL offers ease of operation,” says Ray. “The nature of our business makes this an important consideration. Our order sizes range from 2,000 to 600,000 sheets, making for as many as five changeover during an eight-hour shift. We have to handle both short and long runs equally well.”

Ray explains, “The Maxson sheeter allows us to produce a more consistent product. A clean cut means fewer hickies on the press and less downtime for wash-ups.”

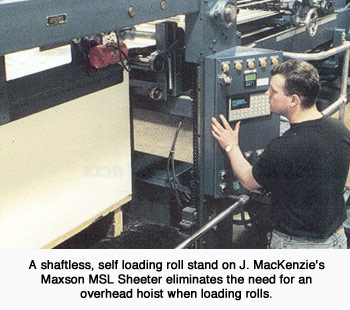

To optimize efficiency during roll changes, J. MacKenzie selected shaftless, self-loading roll stands that eliminate the need for an overhead hoist when loading rolls. The operator simply moves the roll into place and positions the chucks to grip the roll and lift it into position. A roll change is complete in less than four minutes.

Quality control is key to J. MacKenzie. Sheets are checked every 500 to 1,000 for squareness and cutoff, notes Ray. “We hold a

+/- 1/64 for squareness and +/- .030 for cutoff. The cutoff is very relevant to roll quality. The readings on the QC sheets are then recorded and stored in a database by skid number.”

A Success on All Fronts

J. MacKenzie Ltd, in addition to bringing Hammer greater quality control, more flexibility, and reduced operating costs, also functions successfully as a contract sheeter. Says Ray, “We have been lead times shorten up, forcing companies to keep roll inventory on hand. They can utilize J. MacKenzie to warehouse rolls and have them cut on demand.”

The sheeting subsidiary has grown to a three-shift, six-day-a-week operation. “We presently have 14 employees and operate out of a 20,000 square-foot facility,” Ray says proudly. “We have our own skid-building shop, and we have just recently started a cut-size line that is able to package smaller sheets. We are presently able to sheet rolls and then cut them down to 81/2 x 11 in. or smaller and package per customer needs. We offer warehousing and deliveries, and we have our own fleet to deliver products in a just-in-time environment.”

A commitment to the highest quality standards, along with a dedication to serving customers, are the reasons for Hammer Lithograph’s enviable reputation within the printing industry. In addition to earning awards on an annual basis from national Printing Industries of America, the company has been recognized locally for its printing capabilities.

The right combination of facilities, equipment, and people has brought the company to where it is today. By bringing sheeting in-house, both Hammer Lithograph and J. MacKenzie Ltd. Are building on their reputations and continuing to “grow through quality.”

Reprinted from Paper Film Foil Converter, March 1996