In recent years, folding cartons have become highly effective marketing tools, utilizing colorful graphics and appealing finishes to attract consumers.

As packaging appearances becomes more important, folding carton manufacturers are finding quality assurance more important than ever. By implementing a Statistical Process control (SPC) program, one California company is meeting the strict requirements for print quality by carefully monitoring the quality of its end products in-house.

For House of Packaging, the program has meant a greater operating efficiency for its cosmetic and pharmaceutical customers because it reduces the customer’s needs for quality inspection.

“The key elements for our success as a folding carton manufacturer lie in our quality control measures… and state-of-the-art converting equipment,” says co-founder Henry O’Melveny. “What’s happening in the industry is that the customer wants the converter to ensure a quality carton before it leaves the plant. Prior to implementing a quality assurance program, pharmaceutical manufacturers sent in-coming cartons to a quarantined area where their quality personnel checked print quality and color variation of the package.”

“The key elements for our success as a folding carton manufacturer lie in our quality control measures… and state-of-the-art converting equipment,” says co-founder Henry O’Melveny. “What’s happening in the industry is that the customer wants the converter to ensure a quality carton before it leaves the plant. Prior to implementing a quality assurance program, pharmaceutical manufacturers sent in-coming cartons to a quarantined area where their quality personnel checked print quality and color variation of the package.”

According to O’Melveny, the newly-formed SPC program allows for greater production efficiency because it reduces customers’ workloads. “The policy eliminates the need for manufacturers to inspect in-coming orders. Cartons by-pass inspection and go directly to the packaging process.”

Despite the additional steps, the policy has helped boost House of Packaging’s image as a leading supplier of high quality folding cartons in southern California, notes O’Melveny. Over the past year, the company expanded sales by six percent and anticipates the figure to double in 1988. O’Melveny says the company is not only increasing its customer base but is obtaining more orders from its existing customers which include manufacturers such as Neutrogena, Georgio, Syntex and ICI Americas.

O’Melveny reports that quality assurance along every step of the sheeting, printing, die cutting and gluing operations is key to making the SPC program successful.

“Our inspectors carefully check the material as it is being converted from one step to another, but an important element in keeping waste levels minimal and quality levels high is owning equipment that can produce a quality product 100 percent of the time,” says O’Melveny.

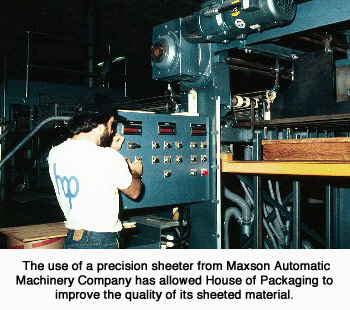

After evaluating the performance of the manufacturer’s equipment, O’Melveny and his partner, Jack Franke, decided recently to purchase a new precision sheeter from the Maxson Automatic Machinery Co.

The selection of a 57″ precision sheeter was the most important decision for maintaining quality standards , notes O’Melveny, because the company’s older sheeter was unable to produce dust-free, high-quality sheeted board on a consistent basis.

“The first step in the converting process is sheeting and we must be able to produce clean, precision-cut board if we want quality end product,” he says. “We’ve found that accumulation of dust on pre-printed clay-coated SBS board is a major cause of hickeys. Our biggest concern in quality assurance is the ability to produce a product free of hickeys since they cause printing flaws and result in a poor-looking carton.”

O’Melveny reviewed several sheeter models and chose a Maxson MSL precision sheeter. The unit offers precise cutting of board ranging from 10 to 32 points, at speeds of 800 to 850 feet per minute.

To ensure the cleanest sheeted board, O’Melveny had a dust collecting system installed on the sheeter. Produced by Web System Inc., the patented system vacuums dust generated by the cutting and slitting of the sheet at the delivery tape section.

“The system utilizes rotating brushes which apply high energy vibration to break embedded fibers and broken clay loose,” says O’Melveny. “As the sheet passes through a narrow tool plate, a vacuum containing compressed ionized air sucks the dust away. The system is highly effective in removing dust as small as 10 microns.”

O’Melveny adds that the installation of a new self-loading shaftless back stand speeds the sheeting operation because it reduces web set-up time. Operable by one person, the back stand can load rolls up to 57 inches wide and 72 inches in diameter.

While upgrading the company’s productivity, O’Melveny and Franke decided to improve the company’s printing capabilities as well. By purchasing a 55″ Miehle-Roland six-color printing press, House of Packaging will be able to print at speeds up to 10,000 sheets per hour, while providing specialized printing jobs for some of its customers.

Once installed, the series 800 press with a tower coater/perfector will enable the company to print, coat and UV cure sheets in-line, saving production time. In addition, by using an aqueous coating instead of a conventional press varnish with the tower coater, the company will be able to produce a glossy, scuff-resistant finish without the use of spray powders, says O’Melveny.

“Some of our cosmetic customers want a smooth, high-gloss finish for their soap, perfume and beauty cartons,” he says. “We took a look at the industry and discovered that there was trend toward specialized carton-making that involves sophisticated look. We want to have the capability to produce this high-quality finish so we meet our customers’ requirements,”

Reprinted from Package Printing & Converting, July 1988