ALL PACKAGING is a folding carton operation that has realized annual double digit growth even during difficult times because its business model is based on delivering creative solutions, dedication to customer service, commitment to quality and investment in the newest and best technology.

The Aurora Colorado – based packaging converter’s success is keyed by a strategy of designing complicated and challenging cartons for businesses whose products are not easily exported overseas – such as pharmaceuticals, cosmetics and consumer goods. With over 130 industry awards for its designs, ALL PACKAGING has carved a niche in the high value paper box market.

The Aurora Colorado – based packaging converter’s success is keyed by a strategy of designing complicated and challenging cartons for businesses whose products are not easily exported overseas – such as pharmaceuticals, cosmetics and consumer goods. With over 130 industry awards for its designs, ALL PACKAGING has carved a niche in the high value paper box market.

The company has fostered a strong sense of loyalty among its 60 employees, by investing in training programs, offering opportunities to advance and scheduling healthy doses of overtime work that provide workers with a sense of security by avoiding furloughs. The result is an experienced, motivated work force.

To maintain the culture of customer responsiveness and quality assurance, ALL PACKAGING has developed its management team from within, typically promoting employees who work their way through the ranks. Using a team of manufacturing managers that have primary responsibilities for specific operations, but knowledge of the entire box making process, provides ALL PACKAGING with deep leadership backup. This support structure allows members of this group to travel off site for seminars, trade shows or to meet with customers without compromising the manufacturing side of the business.

Armed with a creative flair for solving customer requirements, staffed by a skilled work force and directed by a management focused on quality, ALL PACKAGING has invested heavily in technology – from software that allows Customers to proof designs on line, to foil stamping machinery that adds value, to state of the art printing presses. The decision making process of how ALL PACKAGING selects what technology to invest in is instructive as to how the company maintains its competitive edge.

Recently, ALL PACKAGING reviewed its sheeting capacity – an important in house function that impacts timeliness of delivery, print quality and production costs. As Ken Pepper, President of ALL PACKAGING recalls, “We began sheeting in 1990 with the purchase of an old piece of equipment. Then in 1996, we purchased a slightly better machine, which was an improvement, but still slow and cumbersome. As our business grew, the sheeter could not keep up. We were spending $125,000 purchasing sheets from the paper mills. Being located in Colorado, there were no economical alternatives. So buying a modern sheeter became a priority”.

Recently, ALL PACKAGING reviewed its sheeting capacity – an important in house function that impacts timeliness of delivery, print quality and production costs. As Ken Pepper, President of ALL PACKAGING recalls, “We began sheeting in 1990 with the purchase of an old piece of equipment. Then in 1996, we purchased a slightly better machine, which was an improvement, but still slow and cumbersome. As our business grew, the sheeter could not keep up. We were spending $125,000 purchasing sheets from the paper mills. Being located in Colorado, there were no economical alternatives. So buying a modern sheeter became a priority”.

Having determined that sheeting operation needed to be addressed, ALL PACKAGING management considered upgrading their existing equipment, purchasing preowned machinery or buying new technology.

Terry Price, ALL PACKAGING Manufacturing Manager, recollects, “In our studies, upgrading the existing sheeter didn’t seem cost effective. Looking at the growth of our business, we wanted a sheeter that was dependable and one that would grow with the needs of our company over its life. We didn’t want to put a lot of money into the repair costs of a used sheeter versus getting a new sheeter that had more innovative features that could match the state of the art capabilities of our printing presses.”

With the decision to invest in new technology made, ALL PACKAGING developed a criterion for vendor selection. “From our experiences in the Industry”, Price continues, “We identified several players. We considered the capabilities of the machinery, its sturdiness, the responsiveness of the vendor’s customer service, and the history of the manufacturer.”

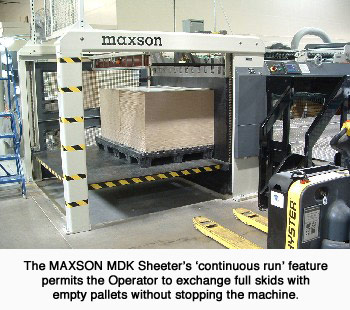

After thorough consideration, ALL PACKAGING purchased the MAXSON MDK Sheeter. Ken Pepper notes, “The primary reasons that we bought MAXSON were they had an excellent reputation for reliability, speed and quality of operation, their sheeter’s foot print was smaller than other offerings and the long term relationship with various other users of the equipment.”

After thorough consideration, ALL PACKAGING purchased the MAXSON MDK Sheeter. Ken Pepper notes, “The primary reasons that we bought MAXSON were they had an excellent reputation for reliability, speed and quality of operation, their sheeter’s foot print was smaller than other offerings and the long term relationship with various other users of the equipment.”

The MDK Sheeter was outfitted with a shaftless, self loading roll stand, web steering system, a dual knife rotary cutter, reject gate, a dust collection system and a “continuous run” feature that permitted the sheeter to run while the Operator exchanged full skids for empty pallets.

Price commented on several features of the MAXSON Sheeter. “Quality of the cut was number one. With the stationary bed knife sheeter we had there were dust issues. Because of our high quality printing we wanted to be sure our sheets were of the highest quality, so it was very important for us to invest in dual knife rotary technology. And again dealing with paper dust, we felt a dust collection system was valuable in delivering a clean sheet.”

“We have seen from our statistical process control reports that the paper dust is minimal and the dual rotary cutter puts out a cleaner sheet. With the new sheeter”, continues Price, “There are less defects in the printing process – fewer hickeys, less wash ups, and less stop times on the presses. And now we go right to the press without running the skids through a jogger aerator, like we used to.”

“We have seen from our statistical process control reports that the paper dust is minimal and the dual rotary cutter puts out a cleaner sheet. With the new sheeter”, continues Price, “There are less defects in the printing process – fewer hickeys, less wash ups, and less stop times on the presses. And now we go right to the press without running the skids through a jogger aerator, like we used to.”

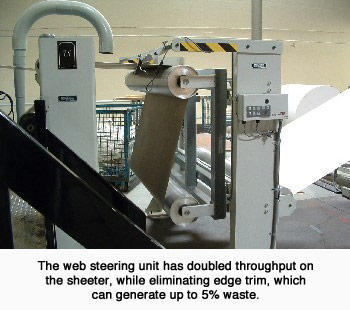

Price identified the web steering unit, positioned between the roll stand and the cutter, as another useful option. Said he, “The web aligner was an excellent feature to have on the sheeter. It gave us the ability to split a double wide roll in half using a single slitter, rather than take an edge trim on both sides to accomplish a finished dimension.

Because we no longer take an edge trim, waste associated with the sheeter has dropped from 5% to 1% – and as low as ¼% on longer runs.” Further, “On our old sheeter, we had to slow down to 550 fpm when slitting so as not to lose the edge trim, while on the MAXSON we can run at full speed.”

The ease of set up on the MDK Sheeter, with its digital inputting of sheet length allows for quicker changeovers. “Our set up time has been reduced by an average of 20 minutes. Because orders can be as little as 1 – 2 skids, some eight hours shifts the sheeter is scheduled for 5 different jobs. And on longer runs, we produce more sheets in less time.

With its compact foot print and quick set up features, the MAXSON MDK Sheeter requires a single Operator.

Since the sheeter can deliver accurate, square sheets at speeds up to 1300 fpm and the compact footprint aids in quick make readies, the MDK Sheeter converts two rolls an hour even with short run work. Because of its high output, Price notes another benefit of sheeter, “As a result, we don’t have to inventory as many rolls.”

ALL PACKAGING has committed to a business model that relies on offering creative packaging solutions, a skilled, quality-focused work force and a forward looking investment philosophy in equipment. As President Ken Pepper sums up, “there are three philosophies we follow every single day. First, we are committed to successful relationships with our customers. Second is our commitment to our employees. We hire ambitious, experienced and motivated persons who want to excel. Our third commitment is to maintain state of the art technology and none better anywhere in the country.” By successfully executing this strategy, ALL PACKAGING has become a leader in the design and manufacture of award winning, top quality products for a range of markets.

Reprinted from The Sheeting Monitor, December 2004