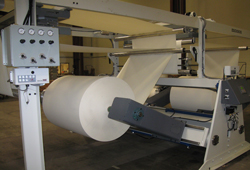

Maxson Automatic Machinery Company (Westerly RI USA) has incorporated into the web conditioning system of its high speed precision sheeters a dancer roll design. The enhancement allows the rotary cutter to accurately maintain sheet length at high speeds regardless of the concentricity of the roll being converted. Rolls damaged during handling can affect sheet length accuracy and operating speed.

Maxson Automatic Machinery Company (Westerly RI USA) has incorporated into the web conditioning system of its high speed precision sheeters a dancer roll design. The enhancement allows the rotary cutter to accurately maintain sheet length at high speeds regardless of the concentricity of the roll being converted. Rolls damaged during handling can affect sheet length accuracy and operating speed.

For example, an egg-shaped roll cause a “taut-slack” web condition as it is unwound. This produces a series of short and then long sheets. Operators compensate for egg-shaped rolls by running the sheeter slower to lessen the “load-unload” condition.A better solution is to install an air loaded dancer roll between the roll stand and the infeed of the cutter. By threading the web around the low inertia dancer roll, web fluctuations are absorbed and provide a smooth flow into the cutter. The responsiveness of the dancer roll can be adjusted by varying the air pressure fed to the dancer roll cylinder.