Sheeting of abrasive materials such as emery paper, sand papers or abrasive cloth can now be achieved with minimal knife wear with a new specialty sheeter from MAXSON AUTOMATIC MACHINERY COMPANY (Westerly, RI USA). The scissors like cutting action of the dual knife rotary design and the MAXSON exclusive cutting clash adjustment greatly extends the knife life over conventional stationary bed knife cutters.

Sheeting of abrasive materials such as emery paper, sand papers or abrasive cloth can now be achieved with minimal knife wear with a new specialty sheeter from MAXSON AUTOMATIC MACHINERY COMPANY (Westerly, RI USA). The scissors like cutting action of the dual knife rotary design and the MAXSON exclusive cutting clash adjustment greatly extends the knife life over conventional stationary bed knife cutters.

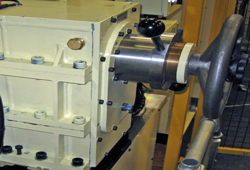

The cutting section includes knives mounted in upper and lower rotating cylinders. Using the exclusive clash arrangement, the Operator can safely adjust the cross cutting blades while the cutter is running, by transversely shifting the upper cylinder across the width of the cutter to increase clash. This allows the Operator to improve cut quality while running the cutter. Quick lock knife adjustments are used across the upper and lower knife cylinders to allow rapid removal and installation of steel rule blades.

With this design, knife changes are completed within 20 minutes. Capable of speeds of over 300 cuts per minute on an 11” (279 mm) cut off, the cutter can slit at multiple intervals across the web and can be custom designed to meet the special requirements of the abrasives converter. The cutting section includes a slitter rig that permits up to 7 piles across the width of the sheeter.

Please contact Nick Datson, Director of Sales & Marketing, for further information by telephone at (401) 596-0162 or by e-mail at ndatson@maxsonautomatic.com