How does a packaging company carry on in business for over 160 years? In the case of Curtis Packaging of Sandy Hook, Connecticut it is a commitment to excellence in meeting the standards of premium markets by investing in talent and technology.

Founded in 1845 by Samuel Curtis as a company that manufactured high quality buttons and combs from hoofs and horns, rigid boxes were made on site to ship the delicate products to major metropolitan centers. With the advent of synthetics that introduced cheaper, plastic buttons, in the early 1900s Curtis began concentrating on printing folding cartons.

Founded in 1845 by Samuel Curtis as a company that manufactured high quality buttons and combs from hoofs and horns, rigid boxes were made on site to ship the delicate products to major metropolitan centers. With the advent of synthetics that introduced cheaper, plastic buttons, in the early 1900s Curtis began concentrating on printing folding cartons.

From 1845 – 1980, five generations of the Curtis family were involved in the business. With no heirs to continue on, Curtis Packaging was sold to the management team that was in place at the time. Within 10 years, Don Droppo Sr. – a partner of the accounting firm that advised Curtis – acquired the company. In 2003, Don Droppo Jr. came on board as Vice President of Marketing, continuing the family business legacy at Curtis Packaging.

Under the Droppo leadership more than $20 million been spent on equipment to automate the workflow and continually improve quality, including three new sheet fed presses, hot stamper, die cutters and gluing machines. As a result, revenues have grown by about 20% annually over the past few years as sales are now approaching $40 million.

A commitment to the latest technology is only one of the contributing factors leading to such accomplishments. “What has made Curtis Packaging successful is reinvesting in the latest technology, then finding and hiring the best people. Having the right technology and giving people the right tools to create the finest packaging is how we have been successful.”, notes the younger Droppo.

Don continues, “We are all about customer service, we feel that sets us apart. In the luxury packaging niche there are demands for UV printing, up to 10 color work, hot stamping, multiple coatings, dispersions, irradiance, and multi level embossing. Curtis Packaging is not just strictly a folding carton operation. Our customers also look to us for graphic design, full prepress facilities, structural design of box displays, and converting capabilities. We are a full service printer, a designer and converter of packaging with everything now done under one roof. We believe our ability to do those things efficiently and on a timely basis set us apart.

In house sheeting was a natural extension of that philosophy.

Curtis Packaging had an outside supplier provide sheeted stock to them for their folding carton boxes. The supplier was reliable and provided timely shipments of sheeted board. But with sales increasing, bringing that operation in house to insure production efficiencies made sense. Says Droppo, “With our innovative processes attracting customers, in house sheeting would give us a lot of flexibility, because orders would increase from an initial 150,000 units to 200,000 units before we went to print. Then we would be faced with holding the order until there was enough sheeted stock available or, if the timing required a rapid order fulfillment, run a second print job later.”

With business growing, management investigated the feasibility of sheeting in house. There were clear advantages to bringing the process in house – the ability to revise quantities of specific sheet sizes to respond to the production schedule and the savings that could be realized by buying roll stock and converting the board themselves. There were also uncertainties. Sheeting was a new operation – what type of equipment was required, what expertise was required to operate the machinery, how much space was required?

With business growing, management investigated the feasibility of sheeting in house. There were clear advantages to bringing the process in house – the ability to revise quantities of specific sheet sizes to respond to the production schedule and the savings that could be realized by buying roll stock and converting the board themselves. There were also uncertainties. Sheeting was a new operation – what type of equipment was required, what expertise was required to operate the machinery, how much space was required?

Because John Guisto, Curtis Packaging’s Vice President of Manufacturing had previous experience with sheeting operations, he was tasked with justifying the investment and recommending the appropriate equipment. Droppo recalls, “Although it was easier to order sheets and not introduce a new operation, business had changed and delivery times to our customers were must tighter. And the financial analysis indicated a payback on the investment in a couple of years. Sheeting for ourselves made sense.”

“At the outset we decided to invest in new equipment instead of used machinery. We did not feel you could retrofit old equipment to new sheeter standards, said Guisto. Interjected Droppo, “It’s part of our overall quality philosophy here. We say that our facility is the ‘silent salesperson’. New machinery, modern technology, factory training sends a statement to our customers and gives them the feeling they are partnering with the right people.”

Guisto explained how he went about recommending the equipment. “Having been in the industry for 40 years, I was aware of the sheeter manufacturers and spoke to several of them. I relied on the manufacturers to update me on the advances in technology, particularly in justifying the value of dual rotary cutters over conventional stationary bed knife design. The vendors convinced me the dual knife rotary was worth the added expense.”

In the selection process, Guisto secured proposals, narrowed the field down to two vendors, and then made his recommendation. “John recommended Maxson,” remembers Droppo, “He spoke highly of their sheeter saying it was the right machine and a quality product. Maxson had a good reputation, they were within a couple of hours of our plant, and their pricing was competitive.”

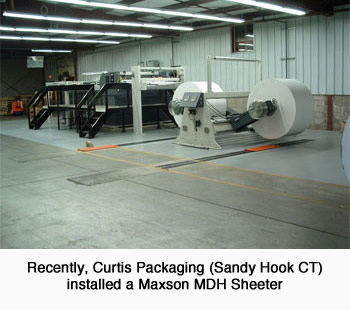

Curtis Packaging bought the MDH Sheeter from Maxson Automatic Machinery Company (Westerly RI). The sheeter is outfitted with a dual position shaftless roll stand, a decurler that could flatten roll set on heavy board grades and a “continuous run” feature that allowed the sheeter to keep running while offloading skids of material. The dual knife rotary cutter provides clean, square and accurate cut offs on lengths up to 65″ long and on board grades up to 0.040″ thick.

Curtis Packaging bought the MDH Sheeter from Maxson Automatic Machinery Company (Westerly RI). The sheeter is outfitted with a dual position shaftless roll stand, a decurler that could flatten roll set on heavy board grades and a “continuous run” feature that allowed the sheeter to keep running while offloading skids of material. The dual knife rotary cutter provides clean, square and accurate cut offs on lengths up to 65″ long and on board grades up to 0.040″ thick.

Aside from the sheeter itself, the other project expenses included site work, operator training, and a clamp truck to handle incoming rolls of board.

A space of 10,000 square feet was allotted for the sheeter operation, which included roll storage, the machine and skidded material. The area where the sheeter was located is humidity controlled to acclimate the stock to the same conditions as the rest of the plant. “The installation of the sheeter was very straightforward. There were no surprises with respect to site preparation or utility services. Within a week of the machine arriving at our facility, our operators were running the sheeter. We allowed for 5% of the machine cost for installation and we were under budget and ahead of schedule,” said Guisto.

“Operator training worked out great,” continued Guisto. “The job was posted and filled internally from staff in the Finishing department. We trained two people for adequate coverage. They were ambitious, hard workers that had mechanical ability and experience setting up other machines. And the sheeter is simple to operate. On the second day of training, the operator was getting printable skids. Within 2 weeks, both sheeter operators, who had no prior experience, were running the sheeter at near maximum speed. The new machines don’t require the finesse of the older sheeters, they run fast and accurately.”

Surprisingly, no additional staff was required to support the sheeting operation. Material handlers that use to get sheets from inventory now come and get skids from the sheeter. The Operator is responsible for preparing and loading rolls.

The Maxson Sheeter has exceeded expectations. Productivity is higher than expected. “The new technology was not oversold to us,” comments Guisto. “Yet we have out produced what was expected. And waste is next to nothing. With the decurling unit provided, we have able to sheet right to the core. Waste from the sheeter is less than one half percent.”

Concludes Don Droppo Jr., “We are very happy, it is a great operation.”

What is next for Curtis Packaging? More of the same – investing in technology and people. Plans include the installation of new folder gluers and a windowing machine. A new quality assurance laboratory is being constructed to insure quality standards are maintained through out the production process.

That is how Curtis Packaging continues to maintain its commitment to excellence – as it has since 1845.