during skid changes achieves over 10 tons per hour.

during skid changes achieves over 10 tons per hour.

detection systems to deliver flat, accurate, quality sheets to the press.

straight in or at right angle to the press, paper or board grades and continuous run with web splicing.

programmable slitters, and rapid pallet discharge that efficiently boost output even on short runs.

and specialty applications that can deliver press ready sheets.

system and allows remote diagnosis by MAXSON service personnel.

to complete a knife change with in 2 hours.

the versatility of running lightweight paper or heavy board grades and ease of operation at an afforable price.

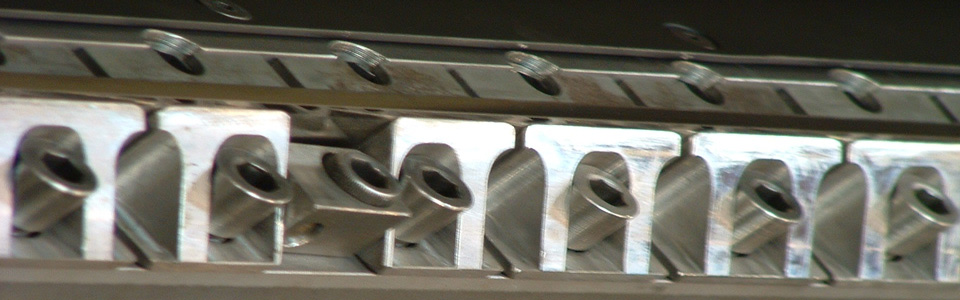

The MAXSON SDFK Sheeter has the exclusive feature of making a blade adjustment to enhance cross cut quality during a production run.