Exclusive Design Permits Cutter Knife Tuning While Running An innovative approach integrated within its dual knife rotary cutter by MAXSON AUTOMATIC MACHINERY COMPANY (Westerly RI) allows an Operator to make adjustments to the cross cutting knives while the sheeter is operating. This feature provides the benefit of cleaning the cut edges of the sheet without […]

Category: MAXSON News and Events

June 13, 2007 – Sheeter for Low Volume Users

MAXSON Introduces Sheeter for Low Volume Users Maxson Automatic Machinery Company, (Westerly, RI), offers a sheeter specifically designed for low volume printers and converters who require a cost effective alternative to purchasing sheeted stock. The MSE Sheeter is designed for operations that need as few as 2000 sheets per order. Outfitted with an AC drive […]

July 9, 2007 – MAXSON Offers Heavy Duty Roll Stand

MAXSON Offers a Heavy Duty Shaftless Roll Stand To Reduce Down Time MAXSON offers a Pivot Arm Roll Stand that is able to handle rolls from 18″ – 84″ (457 – 2134 mm) in diameter and up to 10,000 pounds (4545 kg) in weight at speeds of up to 3000 fpm (914 mpm). Hydraulically powered, […]

August 6, 2007 – Cut to Register/Mark Sheeter Available

Off line Cut to Registration, Cut to Mark Sheeter Available Converters and commercial printers sheeting to a registration mark on a variety of preprinted materials including holographic stock can ensure accuracy with the Cut to Register Sheeter at speeds up to 1000 fpm (308 mpm) from MAXSON AUTOMATIC MACHINERY COMPANY (Westerly, RI USA). The sheeter […]

September 5, 2007 – Drive Retrofit Keeps Older Sheeters Competitive

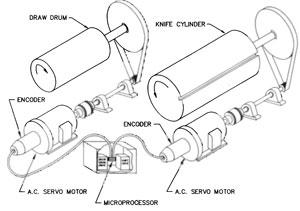

Dual Motor Drive Retrofit Allows Older Sheeters to Remain Competitive The dual motor drive retrofit from Maxson Automatic Machinery Company (Westerly, RI, USA) allows a converter’s older sheeters to remain competitive with today’s precision sheeters. This retrofit replaces a sheeter’s existing wear-prone mechanical transmission or older drive with a more reliable electrical system. This drive […]

October 1, 2007 – Sheeter Meets the Demands of Lenticular Market

Manufacturers of lenticular plastic can now sheet the product at higher speeds than conventional drop shear equipment, while insuring the square, accurate dimensions required by the Printing Industry using a sheeter designed by MAXSON . Lenticular technology, when used in print graphics, gives two dimensional pictures depth and motion. Used increasingly in point of purchase […]

December 6, 2007 – Slitter Dust Removal System

Sheet metal bonnets enclose all but the contact edge of the top slitter blade and bottom slitter ring. Flexible hosing from each slitter is joined to a common manifold that is piped to a blower and duct collection box. The Operator’s lateral positioning of the slitters and setting the depth penetration of the upper slitters […]

January 11, 2008 – MAXSON Announces Multi-Million Dollar Expansion

A 50,000 square foot facility will house fabrication, plasma cutting, metal forming, painting and assembly operations with associated engineering design and support staff. The building is scheduled to be in production by the third quarter of 2008. A large capacity, multi tasking CNC turning mill is the center piece of a capital investment in machine […]

February 11,2008 – MAXSON Offers High Productivity Packaging Sheeter

Two shaftless self loading roll stands cradle rolls weighing up to 10,000 lbs. (4545 kg) in position while the sheeter is running. The overhead automatic splicing system, joins the end of one roll to the beginning of the other while the sheeter speed exceeds 800 fpm (240 mpm), eliminating down time associated with roll changes […]

April 10, 2008 – “Continuous Run” Enhances Sheeter Productivity

At a preset count, the sheeter automatically ramps down to a reduced speed. At the same time, the high and low speed tape sections of the sheeter accelerate clearing sheets from the delivery system, conveying them into the stacker. When the last sheet assigned to the pile enters the stacker, the load table automatically lowers […]