A wavy edge on the slit side of sheets, suggest the bottom slitter rings may have a slight wobble. It could be the slitter rings or it could be the condition of the bottom slitter shaft. First, make sure the inside diameter of the bottom slitter ring is sized properly for the shaft so that […]

Category: FAQ’s

When I run multiple webs of light weight material, it sometimes wrinkles prior to cutting. How do I avoid that?

Wrinkling of webs can be caused by baggy edged rolls, misaligned rolls between the unwind position and the sheeter’s draw drum, severe wrap around rollers, or when running multiple rolls, friction between webs. Here are some suggestions: Baggy edged rolls An unevenly coiled roll has imbalanced tension across the face of the web. In such […]

What can I do to minimize roll change time?

Well run sheeter operations require about 1 – 2 minutes to change a roll for shaftless roll stands and 5 – 8 minutes to change a shafted roll when using air shafts. To minimize roll change time: While the current roll is being sheeted, prepare the next roll to be loaded Strip the wrapper and […]

What maintenance issues should I be prepared to address after replacing my existing rotary cutter’s mechanical drive with an electronic dual drive system?

In older stationary bed knife (or ‘dead knife’) cutter designs a single motor drives the pull roll section and powers a second drive train to change the speed of the revolver relative to the speed of the draw drum. Typically mechanical designs such as expansion pulleys, change gears or gear boxes were used within the […]

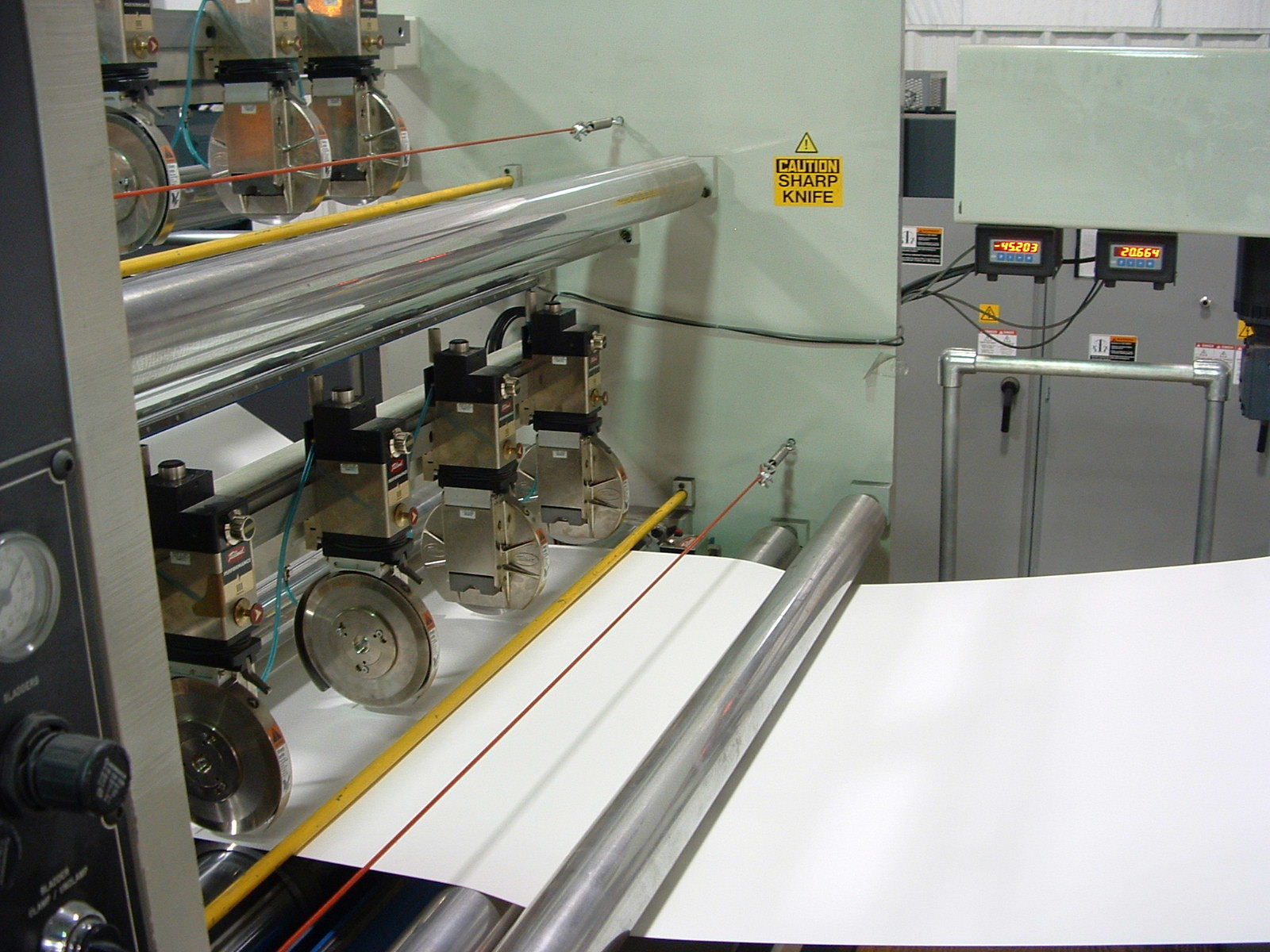

How can I reduce slitter set up time on a sheeter?

A good first step – where possible – is to have your scheduling department arrange sheeter orders so you don’t have to reposition or introduce additional slitters each time for each production run. Most set up time associated with slitting is positioning the bottom rings. Here are some time saving tips: If there are popular […]

Is it possible to increase the speed of an older sheeter?

The short answer is yes – by changing the pulley ratio between the cutter motor and the main drive shaft. But there are several implications to making this change. Make sure that the rotating cylinders, particularly the draw drum and knife revolver, are dynamically balanced. Operating unbalanced components at higher speed will prematurely wear out […]

I have retrofitted an electronic drive onto my cutter to improve sheet length accuracy. Now I have problems with the drives faulting or tripping out. What can I do?

Modern AC frequency drives actually generate “noise” – electrical harmonics and transients that can affect other electrical components. Maxson uses proven grounding methods to minimize noise associated with drives. Among the standard designs employed by Maxson in their dual motor drive retrofits: Inclusion of an isolation transformer between the main line and the electrical cabinet […]

Unlike my older equipment, my new sheeter has a dual motor drive system governing sheet length and a programmable logic controller that manages machine functions. When the sheeter shuts down, how can I troubleshoot the cause?

Actually it is a lot easier to troubleshoot a machine that is controlled with electronics. Most new sheeters have a programmable logic controller (PLC) governing the operations of the sheeter instead of relay logic. Typically a dual motor drive with two motors, two AC drive and a motion controller takes the place of the mechanical […]

How can I increase the productivity of my sheeter? There seems to be a lot of time when the sheeter is not running because the operators are getting and loading rolls, removing skids, and doing paperwork.

It starts with scheduling. Orders should be set up ahead of time so the rolls and skids are available for the job. Next, stage the rolls behind the sheeter so the operators are not waiting for them. An adequate number of skids should also be placed near the stacker so they are readily available to […]

What skill level should a sheeter operator possess?

An operator must be thoroughly familiar with how the machine works. Mechanical aptitude is helpful in learning this. The operator must also know the safety requirements for the machine. Training in the setup procedures is necessary. Experience in web handling is helpful.