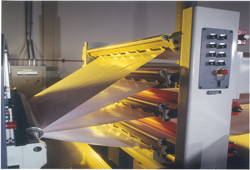

Maxson Automatic Machinery Company (Westerly RI USA) can incorporate bowed rolls in the carrier system of its paper sheeters to smooth out wrinkles by inducing a spreading or widening action on the moving webs. Especially valuable when running multiple lightweight webs, a fixed bowed roll is placed before each decurl unit. The roll is designed for the application, with the amount of bow determined by the caliper range and material being sheeted. By adjusting the position of the bow, relative to the web flow, the roll tightens the center or the edges of web compensating for bagginess that can result in wrinkles.

Maxson Automatic Machinery Company (Westerly RI USA) can incorporate bowed rolls in the carrier system of its paper sheeters to smooth out wrinkles by inducing a spreading or widening action on the moving webs. Especially valuable when running multiple lightweight webs, a fixed bowed roll is placed before each decurl unit. The roll is designed for the application, with the amount of bow determined by the caliper range and material being sheeted. By adjusting the position of the bow, relative to the web flow, the roll tightens the center or the edges of web compensating for bagginess that can result in wrinkles.

In cases where there is a wide range of materials and grades, a variable bow roll can be used to adjust the amount of bow. This allows the Operator to adjust the degree of bow in responding to fickle spreading demands and changing circumstances.