As the sheet packet is conveyed from the cutter to the piler, it passes between the two suction headers. At the point of application, ionized bars reduce static build up. The top, bottom and edges of the cut packet are vacuumed clean of loose fibers without contacting the sheets. The dust particles pass from the […]

Author: Scott

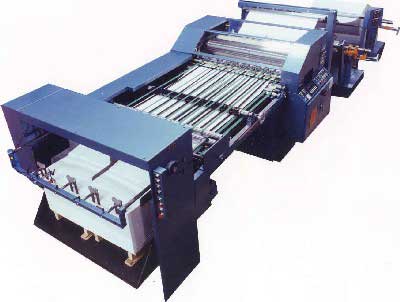

April 13, 2010 – Dual Position Roll Stand Enhances Productivity

The Dual Position Roll Stand is able to handle two rolls. Each position can lift a roll up to 84″ (2134 mm) in diameter and up to 7,000 pounds (3,180 kg) in weight at speeds of up to 3000 fpm (914 mpm). Hydraulically powered, each position loads a roll by lowering both arms and then […]

June 02, 2010 – Non Marking Overlap Carriage Allows Higher Speeds

The overlap roll is geared such that the surface speed of the black rings matches the speed of the slow speed tapes. In this way the sheet decelerates evenly across the width of the delivery system by speed, rather than nip pressure. The uniform contact across the sheeter eliminates sheet skewing, enhancing pile quality. The […]

July 12, 2010 – Web Carrier Insures Wrinkle Free Sheeting

The system can be threaded from floor level, it assures wrinkle free web flow into the cutter and avoids ‘web wander’. The low profile of the web carrier framework allows an Operator to safely and quickly thread the webs of up to 6 unwind Please contact Brent H. Burdick, Director of Sales & Marketing, for […]

August 5, 2010 – MAXSON Offer Free Sheet Length Calculator

The calculations are provided in both metric and imperial dimensions. Easy to use, the instructions on how to use the slide rule are outlined on the calculator. It is free of charge. Please contact Nick Datson, Director of Sales & Marketing, for this slide rule by telephone at (401) 596-0162 or by e-mail at ndatson@maxsonautomatic.com.

September 08, 2010 – MAXSON Web Steering Design Lowers Waste

The web steering system includes a sensing head, and two parallel rolls on a common frame and pivoting carriage mounted within the web conditioning frame. Web aligners arrangements can be configured for multiple roll sheeting. The sensing head detects the edge of the web or a line in the case of preprinted material, sending a […]

Product Catalog

Products by Category Product by Industry A – Z Product List

2000-Present ::: A Commitment to the Future

To insure competitive pricing and prompt delivery schedules, in 1995 Maxson undertook a multimillion dollar capital program to modernize its machining and fabrication capacity. Over the next three years, Maxson devoted resources to computer numeric controlled (CNC) machine tools, state of the art welding equipment, computer aided manufacturing (CAM) programming, advanced painting and finishing facilities […]

1986-2000 ::: Offering Technological Solutions to a Global Market

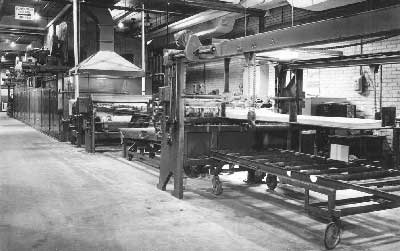

In 1987, Maxson expanded its Airport Road facility more than tripling its floor space. The machining and fabrication operations were consolidated under one roof and assembly area was added. The previous year, Joseph Clancy died and Merton L. Matthews became Maxson’s sixth President. Within 10 years, complete Company ownership would be transferred to the Matthews […]

1970-1986 ::: An Allegiance to the Converting Industry is Born

In a decision that would chart the Company’s future, Maxson concentrated on sheeting equipment for the converters of paper, board, and specialty products. This diverse market required tailored designs for each industry, demanded user friendly sheeters that were easily maintained and provided a quick return on investment. These needs played to Maxson’s strengths of engineering […]