In a tough situation? Call Situation Materials, whose niche lies in unusual, specialty materials, which often mean shorter runs. But shorter runs are no longer a problem for them, thanks to the addition of a Maxson sheeter that produces press-ready sheets (no guillotine trimming necessary) and features a shaftless, self-loading back stand and an air-loaded slitter for faster setup, to name just a few of its features.

Located in Twinsburg, Ohio, Situation Materials was established in 1974 to operate as an odd-lot dealer in paper. Over the years, this family-owned company has expanded its product line to include specialty materials. Pressure-sensitive and non-pressure-sensitive films, foils, plastics, and papers are the company’s forte.

With customers located throughout the United States and Canada, as well as South America, Mexico, and the Middle East, Situation Materials has earned a reputation as a dependable odd-lot supplier. Part of this success has been due to their commitment to providing prompt service, even when orders are small or odd-sized.

With customers located throughout the United States and Canada, as well as South America, Mexico, and the Middle East, Situation Materials has earned a reputation as a dependable odd-lot supplier. Part of this success has been due to their commitment to providing prompt service, even when orders are small or odd-sized.

The desire to further improve service was central to the specialty converter’s decision to add in-house capabilities. In 1987, the company expanded its operations to include converting with the addition of a 54-in.-wide Dusenbery 638 slitter/rewinder. The decision proved to be cost-effective. A second 92-in.-wide Cameron 630 slitter/rewinder was added in 1989.

Recently, Situation Materials faced the problem of supplying sheeted stock. “We had material in-house that needed to be sheeted. However, we had a difficult time finding a source that could do a good enough job, quickly and cost-effectively,” says Bonnie Aronoff, president. In many instances, the company had to wait three to four weeks for delivery. Plus, up charges for sheeting and guillotine trimming doubled the cost.

As the demand for sheeted stock represented a growing part of the company’s business, Situation Materials decided to investigate in-house sheeting. They chose a 65-in.-wide Maxson MSS sheeter.

“We were impressed with the sheeter’s rugged construction and its ability to produce press-ready sheets. Another advantage was that the MSS required only a single operator,” says Aronoff. The MSS accommodates sheets size from 8 ½ x 11 in. up to 60 x 42 in.

Options right on the money

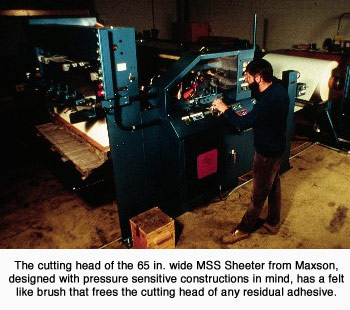

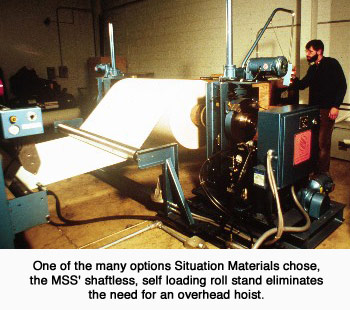

The cutting head of the MSS sheeter was designed with p-s constructions in mind. It features a felt-like brush that frees the cutting head of any residual adhesive. Maxson’s options were right on the money, too, and include an automatic unwind stand with edge guidance; a shaftless, self-loading back stand; decurl unit with dancer roll; air-loaded slitter rig; close tolerance drive; and an air delivery system. These options were selected to optimize the sheeter’s performance and reduce downtime during setup.

For Situation Materials, quick make ready was an issue because the average from 1,500 to 2,000 sheets. The permanently attached chucks, which grip the roll and lift it into position, eliminate the need for an overhead hoist or fork lift when loading rolls. As a result, roll changes reportedly are complete in less than five vs. 20 minutes with a shaft-type back stand.

As another option, a dancer roll mounted to the decurl frame absorbs web fluctuations caused by out-of-round rolls. This arrangement reduces sheet-length variation when sheeting “egg-shaped” rolls. Air-loaded slitters were installed as a time-saving option. The design offers safety as well as set-up advantages over spring-loaded slitters. “Having air-loaded slitters has really made a difference because we slit the majority of time,” says Aronoff.

Since most of the material sheeted at Situation Materials is value-added, keeping waste to a minimum is very important. The MSS sheeter has a close-tolerance drive that provides press-ready sheets. “When we sheet an 8 ½-by-11 size,” says Aronoff, “the accuracy is dead on.” Since the new sheeter came on-line, the company’s waste percentage has dropped by 25 percent.

The MSS has an air delivery system at the pile, which helps improve pile quality when sheeting light-weight materials. “We recently sheeted an order of 7-mil micro porous stock. Air at the pile really made a difference on the longer cutoffs,” states Aronoff.

The new sheeter operates at an average of 175 fpm. These speeds take into account sheeting specialty materials. She explained, “Since most or our stock is off-spec, the operator must run the sheeter slow enough to inspect the materials.

“The Maxson installation has been the best situation we’ve experienced in terms of bringing in new equipment. Our operator was trained and the sheeter was up and running within a couple of day.” After a few months, the Maxson sheeter has already lived up to Aronoff’s expectations. “Sheeting in-house has helped our service considerably. Now, our lead times average two days.”

Sheeting in-house has also opened up new markets, particularly specialty trade converting. Trade converting now comprises 10 percent of Situation Materials’ sales. “We commonly run trials for companies launching new experimental products. Our plans are to expand in this area,’ says Aronoff confidently, knowing the right combination of people and equipment is in place to meet the demands of these companies.

Reprinted from Converting, September 1993