In 1987, Maxson expanded its Airport Road facility more than tripling its floor space. The machining and fabrication operations were consolidated under one roof and assembly area was added. The previous year, Joseph Clancy died and Merton L. Matthews became Maxson’s sixth President. Within 10 years, complete Company ownership would be transferred to the Matthews family.

The last decade of the 20th century witnessed the heaviest investment in technology and talent in Maxson’s history. The Company enlarged its product line to include high speed dual knife rotary sheeters and expanded into offshore markets.

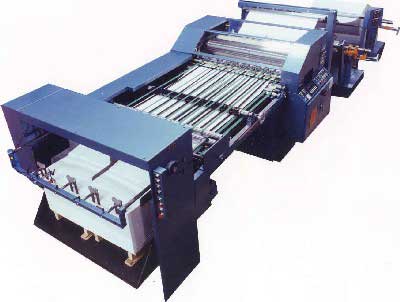

Maxson MSP Sheeter

The technology of the 1980s was giving way to advances of the 1990s. Nowhere was that more apparent than in electronics. Where DC drives and relay logic once existed, Maxson introduced maintenance free AC drive technology, compact, dependable programmable logic controllers, and self diagnostic operator interfaces. Maxson launched a new stationary bed knife sheeter for the converting and printing markets that maintained ± 0.015″ (± 0.381 mm) sheet length accuracy.

In 1991, an addition created new, larger spaces for the Engineering Department, outfitted with computer aided design (CAD) systems and the Sales & Marketing Department, equipped with sophisticated database programs for sales management and desktop publishing capabilities.

Maxson’s Airport Road facility (1992)

In 1992, Maxson sold its first high speed dual knife rotary sheeter, offering the market a compact, versatile machine that could convert either small or large orders of both paper and board grades. In quick succession, Maxson introduced to its DFK Sheeter low inertia cutting cylinders to provide high speeds on short lengths, in line cut to registration capabilities, and continual run systems that maximized production.

Maxson DFK Sheeter with Dual Stacking Stations

At the same time, Maxson aggressively pursued the export business. To meet the concerns of after sales service, Maxson partnered with component suppliers that offered global support, used metric bearings and fasteners throughout the machine design, outfitted operator controls in the Customer’s native tongue, and enlarged the Customer Service Department staff to provide 24 hour a day support. In response, offshore sales swelled to a third of order intake.