In a decision that would chart the Company’s future, Maxson concentrated on sheeting equipment for the converters of paper, board, and specialty products. This diverse market required tailored designs for each industry, demanded user friendly sheeters that were easily maintained and provided a quick return on investment. These needs played to Maxson’s strengths of engineering excellence and commitment to customer satisfaction. From envelopes, to folding cartons, to photographic films, to laminates for counter tops, Maxson distinguished itself from other manufacturers by offering sheeters that were detailed to meet the specific needs of the customer.

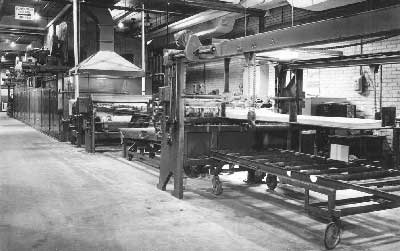

Maxson MSH Sheeter, Robertson Paper Box, Montville CT USA (1973)

This approach proved successful, as Maxson broadened its product lines and flourished. In 1974, Maxson built its first dual knife rotary cutter – a 300 fpm (90 mpm) line capable of sheeting up to 13 webs of 110# kraft paper in lengths up to 14 feet long. Unable to expand further at its site, in 1977 Maxson built a new facility for its sales, engineering and assembly operations. Located within a mile of the new plant, the former facility was dedicated exclusively to machining and fabrication work.

Maxson’s Airport Road facility (1977)

The first half of the 1980s brought the most challenging times since the 1930s’ Great Depression. With 21% inflation rates, high unemployment, and unfavorable foreign exchange the sheeter market collapsed, weakening equipment manufacturers. As most of Maxson’s US competitors were forced into bankruptcy or asset mergers, Maxson deepened its commitment to the Converting Industry. During this period, Maxson began offering retrofit kits to upgrade existing equipment, designed a new class of sheeter targeted for entry level converters, providing highly customized sheeting lines for specialty applications like films and foils and introducing shaftless roll stands as a product offering.

Maxson MSH Sheeter

G. B. Goldman Paper, Philadelphia PA (1983)