In 1932, Maxson Automatic Machinery Company was incorporated, ushering in the present day legal form of the company. The corporate officers were Charles Maxson, President, Julian Maxson, Vice President, Louis Matthews, Secretary and Joseph Clancy, Treasurer. These officers were also the principals of the company.

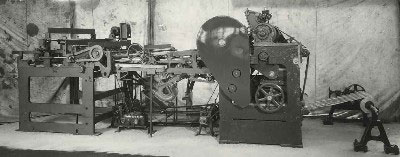

SD WARREN, Cumberland Mills, Maine USA (1931)

In 1939, C. B. Maxson passed away. Maxson’s legacy, in addition to his founding role of the company that bears his name, is his engineering ingenuity that resulted in 18 patents involving sheet conveying and piling systems. Julian W. Maxson succeeded his father as President.

Near this time, because of demands caused by World War II, Maxson encountered difficulties in securing manufactured parts. Born of necessity, the transformation from an engineering company to an equipment manufacturer began as Maxson began machining and assembly of its designs in Westerly RI.

During the 1940s, Maxson continued to develop and improve upon methods of conveying sheeted product into well jogged stacks. In this time, Lou Matthews amassed more than a dozen patents that advanced the sheeting process. These innovations enhanced productivity (creating the ability to continually run a sheeter while off loading full skids), improved runnability on lightweight and sensitive materials (by introducing a driven overlap carriage that avoided marking the cut packet and pioneering the use of air to control sheet flow through the delivery system) and insured product quality (offering the first full web inspection and reject tape system).

With the end of World War II and the rebuilding of Europe, Maxson’s offshore sales surged and in 1946, the company built a new engineering and manufacturing facility in Westerly that would ultimately double in size.