Today’s highly competitive folding carton climate makes servicing customers a top priority. Ling Industries, Warwick Quebec, has made this priority a part of its business credo.

In the early 1950s, Ling Industries was a commercial printer servicing the local market. It was in the 1960s that paper board boxes were integrated into the production process. This new line grew to proportions that required a significant change and the commercial line of products was eliminated permanently. In the late 1970’s, a large customer experiencing supply difficulties with their regular supplier of folding cartons due to a work stoppage, got some of the business produced at Ling Industries. After satisfactorily filling an initial order and with the labor strike continuing, Ling Industries was rewarded with the customer’s ongoing business. This customer driven focus introduced Ling Industries to the Paperboard Industry and in time carved out a niche as a folding carton specialist.

Over the years, the privately held Ling Industries prospered. In 1993, with sales of CAN $ 48 million, Ling Industries was acquired by Rock Tenn (Norcross, GA). Now with annual sales of CAN $ 115 million, Ling Industries employs between 400 – 450 workers in its 450,000 square foot facility. From its Warwick Quebec location Ling Industries services the Canadian, New England and eastern New York personal care, facial tissue and food and beverage markets.

Over the years, the privately held Ling Industries prospered. In 1993, with sales of CAN $ 48 million, Ling Industries was acquired by Rock Tenn (Norcross, GA). Now with annual sales of CAN $ 115 million, Ling Industries employs between 400 – 450 workers in its 450,000 square foot facility. From its Warwick Quebec location Ling Industries services the Canadian, New England and eastern New York personal care, facial tissue and food and beverage markets.

Servicing the customer is preeminent. As Patrick Giguère, Material Handling Manager explains, “We work with the end user from the ‘get go’. With our Custom Design Program we’ll take a client’s product and ask, “What type of box do you want? Where is it going to be retailed? How do you want to display it?” Next, we develop a conceptual model. Then we work with the Customer to refine the box design.”

Once final approvals of design and graphics are received, Ling Industries can deliver a standard box within two weeks – emphasizing how closely they work with their purchasers’ schedules to insure the product is on retail shelves on time.

To meet deadlines, Ling Industries has invested in machinery that provides it with the versatility to meet the market’s demands and the flexibility to schedule quick turnarounds. There are 33 different production lines ranging from printing presses to metal edgers, to die cutters, to waxers, to folder gluers – all playing an integral role in producing 25 million boxes a week.

How Ling Industries chooses to invest in capital projects provides insight into how deep their commitment to customer service is rooted.

Consider the sheeting process. Until Rock Tenn’s acquisition of Ling Industries, as many as three outside converters supplied sheeted stock to the printing operation. To improve delivery schedules, in 1995 Ling Industries began converting on site with a Maxson sheeter previously used by a Rock Tenn mill.

As business grew, the printing department added more sheet fed presses. Although the sheeter was converting more than 80 tons of recycled board daily, it was unable to keep up with production demands. Company management found itself still relying on external suppliers for sheets. The lead times of the board was affecting Ling’s ability to quickly respond to its customers’ demands. As Giguère relates, “If a Customer called us with an emergency order on Friday night, we could start on the job that very night, so that the printing department can have the board Saturday morning. That’s not feasible when there are lead times of trucks to schedule, delivery of material to an off site location and having someone else’s sheeter up and running at a moment’s notice. So in order to give us more flexibility, we began promoting the idea of additional sheeting capacity.”

From the outset, plant management considered investing only in new equipment. Recalls Giguère, “We were looking for state of the art technology and automation to realize maximum productivity. We didn’t want to get a used piece of equipment and spend time bring it up to current standards.”

There were two significant factors that determined the parameters of Ling’s new sheeting equipment – the size of their printing presses and the trim of a supplier’s board machine.

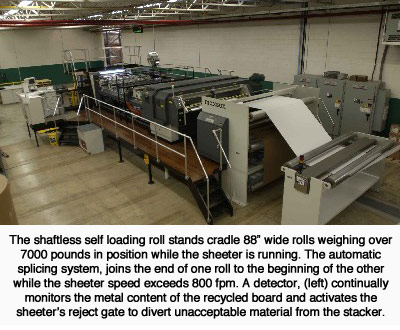

Ling Industries has two 40”, three 55” and one 63” format sheet fed presses – so at a minimum the sheeter needed to handle “short grain” runs on the widest printing press. One of the recycled mills that supplied the folding carton plant had an 88” wide board machine. Intuitively, that seemed like a natural match for the width of a new sheeter. Explained Giguère, “When we looked at that, we realized it was very efficient because we could service two of our press sizes on a double width format. So in terms of throughput, every cut produced two sheets.” Thus the width of the sheeter was established.

Ling Industries has two 40”, three 55” and one 63” format sheet fed presses – so at a minimum the sheeter needed to handle “short grain” runs on the widest printing press. One of the recycled mills that supplied the folding carton plant had an 88” wide board machine. Intuitively, that seemed like a natural match for the width of a new sheeter. Explained Giguère, “When we looked at that, we realized it was very efficient because we could service two of our press sizes on a double width format. So in terms of throughput, every cut produced two sheets.” Thus the width of the sheeter was established.

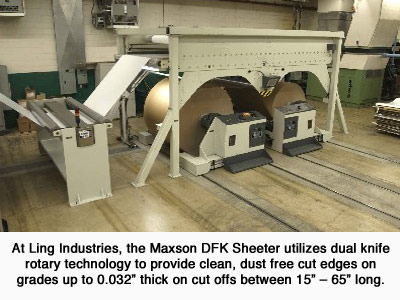

Ling Industries specifications for the new sheeter addressed the latest in automation to insure quality and productivity. The sheeter would include a computerized high speed splicer to eliminate downtime associated with roll changes. A detector to monitor the level of metal content in the recycled board, diverting unacceptable sheets from the stacker was specified. Programmed web conditioning systems to automatically compensate for the amount of decurl to be applied to insure a flat sheet was requested. A dual knife rotary cutter was selected to provide a cleaner, quieter cut than the existing stationary bed knife sheeter. Finally, a count actuated quick pallet discharge system, capable of offloading full skids while the sheeter continued running without the loss of any acceptable sheets was identified as a useful option.

Using the sheeter’s “continuous run” feature and rapid pallet discharge system, Ling Industries maximizes production by removing a full skid and inserting an empty pallet while the operation continues, without the loss of any acceptable sheets

The selection committee considered three sheeter suppliers. Ultimately, they chose the DFK Sheeter from Maxson Automatic Machinery Company, (Westerly RI). “It made sense to buy from a supplier we already knew, one we already dealt with, and whose equipment already had proven it could do the job. Maxson was the best fit for us based on their reputation for service and value.” stated Giguère.

Within 3 weeks of delivering the first shipment of the equipment, useable sheets were being converted for the press room. Even training of the French speaking operators presented no problem because of the “hands on” approach of Maxson’s installation team and referencing controls in the local language.

The emphasis on automation has paid large dividends. Giguère identifies the non stop operation at both ends of the sheeter and the consistent, trouble free performance of the dual knife rotary cutter and rejection gate as reasons why the DFK Sheeter averages approximately 5 tons/hour while generating less than 1% of waste. As a result, the project’s two year pay back forecast is on schedule.

Larger sheet runs, (in excess of 60,000 sheets), are usually run on the DFK Sheeter. Typically, three size changes are made every 24 hours on the newer sheeter. Smaller production orders are run on the other Maxson sheeter. Despite averaging 12 size changes a day, the older Maxson still produces 3½ tons an hour while generating less than 1.25% waste.

Management’s commitment to service means keeping the printing presses running to meet tight delivery schedules. Ling Industries’ 40” presses run at speeds of up to 15,000 sheets per hour. But the older 65” sheeter produces 10,000 sheets an hour. So the sheeter needs to be a day ahead of the printing schedule. Still, service means responding to ever changing situations. The addition of the second sheeter has made choreographing even last minute press room schedule changes easier.

What’s on the horizon for Ling Industries? More of the same. Opportunities in expanding flexographic printing are being considered. Like the recent sheeter project, the questions of what equipment is to be put in, what machinery is to be replaced, and how is this going to be done are only asked after the question, “How can we best serve our Customers?” is answered.

Reprinted from Converting Today, May 2003