Bok Industries is a company that places service above all else. Whether it means turning around in one day, or providing a customized design service, Bok Industries will do what it takes to satisfy their customers.

For the past 35 years, Bok has been a quality producer of presentation binders, loose leaf products and packaging. Serving a customer base concentrated East of the Rockies, Bok’s customers include Eastman Kodak and Xerox Corporation. The company employs 250 workers at its 100,000 sq. ft. facility in Leroy, NY.

In addition to sheeting, silkscreen printing, stamping, and heat sealing capabilities, Bok Industries has a computerized graphics department complete with an in-house designer. The company’s machinery operates two shifts per day.

Until recently, Bok sheeted its flexible PVC stock on an older sheeter. While this unit had served the company for more than 20 years, it was slow and inaccurate. Operators had to hand stack the material and then cut down to an exact size on a guillotine trimmer, which created an additional labor step.

As Gary Lomber, the company’s operations manager explains, “In order to hold the tight registration on our bindery equipment, we had to trim anywhere, we had to trim anywhere from ¼ to ½ inch off of each sheet. This made sheeting the largest bottleneck in our manufacturing process.”

In an effort to streamline its operation, Bok decided to investigate replacing their older sheeter with a new unit. After a careful review, the company selected the MSS Sheeter from Maxson Automatic Machinery Company (Westerly RI).

Lomber said, “With the Maxson the sheet length and squareness accuracy was dead on.” The ability to automate stacking further increased productivity. He adds, “We no longer need two people dedicated to hand stacking material.”

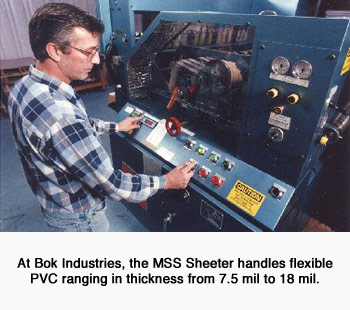

For Bok operation, the MSS Sheeter handles flexible PVC ranging from 7.5 mil up to 18 mil thickness. As an options, the company selected an air loaded slitter rig which slits the web into several streams across. With this capability, a wider roll can be slit into as many as six piles across the web.

Depending upon the material being sheeted, the MSS operates at speeds between 125 to 200 fpm. These speeds represent a threefold increase over their older unit. In Lomber’s opinion, this has been the greatest savings realized. “In the past, when we had 10,000 piece order we would panic. With the Maxson, this is no longer problem. There’s capacity on this machine that we’re not even using yet.”

The ability to operate more efficiently complements Bok Industries’ customer service philosophy. Lomber explains, “Since the Maxson sheeter came on-line, our lead times have shrunk tremendously. If need be, we now have the capability to turn orders around in one day.

The purchase of a Maxson sheeter has also opened up opportunities for future growth. “We are now in the position to take on new business. We can meet the price crunch or delivery date to secure an order. With the Maxson, we are more competitive. In fact, we’ve been able to reduce our prices and still hold our margins.”

Reprinted from The Sheeting Monitor, June 1996