Progressive Converting, Neenah, Wis., is not yet two years old, but its owners believe their focus on short-run, value-added work instead of commodity, low-margin production has lead to a competitive advantage is being honed with the help of a Maxson MSL sheeter.

By targeting a diverse customer base, Progressive Converting can deliver a host of custom-cut products, including fine papers, lightweight metallized stock, and board grades up to 0.028 in. thick.

Cut-to-register is prime example of how Progressive converting has customized process. The company can sheet preprinted stock ranging from watermark papers to holographic materials. Partner Mark Reinhardt says, “Registration sheeting has really set us apart from the competition. This work has supplemented our business quite nicely.”

Cut-to-register is prime example of how Progressive converting has customized process. The company can sheet preprinted stock ranging from watermark papers to holographic materials. Partner Mark Reinhardt says, “Registration sheeting has really set us apart from the competition. This work has supplemented our business quite nicely.”

Without question, the nature of Progressive Converting’s business dictates flexibility. Finding the right equipment to handle both trade sheeting as well as registration work was essential.

After studying both new and used sheeting equipment, Progressive Converting selected Maxson Automatic Machinery’s MSL sheeter. “The Maxson gives us the accuracy we were looking for and the flexibility to sheet both board and paper,” explains Reinhardt.

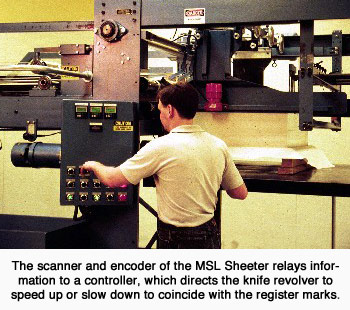

The sheeter has a cut-to-register system that includes a scanning device, a controller, and an encoder. The scanning device is mounted on the draw drum and detects the register mark as the web feeds into the sheeter, while the encoder monitors the position of the knife revolver. The scanner and encoder relay information to the controller, which directs the knife revolver to speed up or slow down to coincide with the register mark.

At Progressive Converting, the cut-to-register system can tolerances of + /-0.030 in. at speeds up to 500 fpm. “When sheeting to register mark, the tighter the tolerances, the better,” says Reinhardt. “The advantage of our system is that you can tighten your parameters more closely.”

When sheeting without a register mark, Progressive Converting also requires a high level of accuracy. “Many trade converters have old equipment, requiring secondary trimming. We saw an advantage in not having to guillotine trim,” says Reinhardt.

Saving money is the biggest advantage, according to Reinhardt. “From a spoilage standpoint, they have to trim larger sheets. We yield more sheets out of a paper.”

The Maxson sheeter has a close tolerance drive that provides press-ready sheets. “Since the sheeted stock goes directly onto a customer’s four-color or six-color press, squareness level of

+/- 0.015 inch,” adds Reinhardt.

Optional help

Equally important was the issue of dust. Reinhardt notes, “A printer needs a square sheet, a reasonably accurate cutoff, and above all, a clean sheet. For this reason, the company selected the PEN MAM dust collector as an option. The system utilizes top and bottom headers that clean without contacting the surface of the sheet. “I like the system, and there is a noticeable difference in the quality of the finished product,” Reinhardt says.

To speed setup during roll changes, a Maxson shaftless, self-loading roll stand was also selected. Reinhardt explains, “When sheeting board stock 0.010 inch and heavier, I couldn’t see the sheeter down for 15 minutes every hour for a roll change. With a shaftless roll stand, we’re up and running in three minutes.” The roll stand is also equipped with an guidance system to aid registration sheeting.

The Maxson sheeter has the flexibility to handle short and long runs efficiently. The company works mostly in truckloads of customers’ stock, but it does sheet orders ranging from 5,000 to 10,000 lb.

Targeting a diverse customer base has proven to be a successful approach for Progressive Converting first year of operation. As the company’s second anniversary approaches on Jan. 1, 1993, plans are underway to expand in several areas. A second, identical MSL sheeter from Maxson has been ordered, completing the first phase of expansion. The second phase will be the construction of a new converting facility, with a move-in date scheduled for the end of 1993.

“Our experience, combined with the ability to listen to what our customer want, has brought us to where we are today. We’re not afraid to expand in a completely different direction if the opportunity is there,” says Reinhardt.

Reprinted from Converting, September 1992