In Utah Paper Box’s conference room, a plaque reads, “True quality is defined as meeting and exceeding the customer’s specifications in an efficient and timely manner-Doing it right the first time, every time.” These words underscore Utah Paper Box’s philosophy of doing business, and offers some insight into how this Salt Lake City-based box plant has achieved success over the past 70 years.

When the company was founded in 1923, rigid and set-up box work were the main focus of operations. During the 1970’s, market dynamics and a shift in consumer demand changed this focus to folding cartons. Today, Utah Paper Box is a leading manufacturer of folding cartons, with an emphasis on high quality work. Serving a customer base concentrated throughout the United States, the company supplies boxes for a wide range of uses, including software packaging, retail products, medical supplies, as well as pharmaceuticals.

Utah Paper Box’s ability to produce high quality folding cartons is due in part to their commitment to investing in the latest technology available . Recent additions to the company’s pressroom include three 6-color MAN Roland presses, two with tower coaters. This equipment, along with an existing 4-color MAN Roland unit, represents Utah Paper Box’s flagship presses. Additional equipment includes 6 smaller presses offering varied capabilities, 5 Bobst die cutters, windowing equipment, as well as 3 stamping presses for embossing work.

Utah Paper Box’s ability to produce high quality folding cartons is due in part to their commitment to investing in the latest technology available . Recent additions to the company’s pressroom include three 6-color MAN Roland presses, two with tower coaters. This equipment, along with an existing 4-color MAN Roland unit, represents Utah Paper Box’s flagship presses. Additional equipment includes 6 smaller presses offering varied capabilities, 5 Bobst die cutters, windowing equipment, as well as 3 stamping presses for embossing work.

As Utah Paper Box increased its printing capacity, this also resulted in an increase in their sheeted stock requirements. Over time, this growth in demand created a production dilemma. Recalls Tom Boner, Utah Paper Box’s purchasing manager, “Our existing sheeter had been a real workhouse, although it lacked an overlap for faster speeds. As we added more printing equipment, the sheeter just couldn’t keep up. We needed something that could give us the capacity standards.”

While increased production was an important consideration, quality assurance was the main requirement. Boner notes, “In selecting a sheeter, our motivating factor was quality.” After investigating the several models available, Utah Paper Box selected the MSL Sheeter from Maxson Automatic Machinery Company

(Westerly RI). He explains, “We spoke to other people in the industry and the general consensus pointed us to Maxson.”

At Utah Paper Box, the MSL Sheeter handles folding carton stock in calipers ranging from 0.010 inches to 0.026 inches. The Maxson primarily sheets SBS grades, as well as SUS board for use in producing high quality cartons.

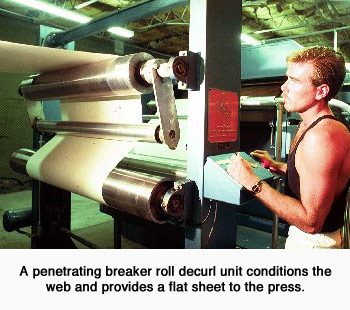

Along with the new sheeter, Utah Paper Box selected several equipment options designed to enhance quality and increase production. These include a penetrating breaker roll decurl unit with dancer roll, a close tolerance drive system, a PEN MAM dust collector and an extending grid for continuous operation.

The penetrating breaker roll decurl conditions the web and provides a flat sheet to the press. The unit’s double direction feature permits decurling in two directions. To absorb web fluctuations when sheeting egg-shaped rolls, a dancer roll was mounted within the decurl frame.

The penetrating breaker roll decurl conditions the web and provides a flat sheet to the press. The unit’s double direction feature permits decurling in two directions. To absorb web fluctuations when sheeting egg-shaped rolls, a dancer roll was mounted within the decurl frame.

The Maxson sheeter had a close tolerance drive system to provide press-ready sheets. Boner comments, “On our older sheeter, accuracy was off by as much as 1/12 of an inch. The MSL sheets more accurately, and as a result, we’ve realized a 30 percent reduction in waste.”

Because clean sheets are a prerequisite for a quality printed piece, Utah Paper Box selected the PEN MAM dust collector as an equipment option. Remarks Boner, “Dust is one problem we try to avoid. The dust collector cleans the sheet and reduces hickies on the printed stock. Another advantage is it has also cut down on the frequency of wash-ups.”

To improve throughout, the Maxson sheeter is equipped with an extending grid. This device reduces downtime by allowing continuous operation during skid changes. The grid fingers shoot out over the pile, collecting the sheeted stock until the operator moves a new skid into position. Says Boner, “Since many of our orders are long runs, the grid helps to keep downtime to a minimum.”

Since the new sheeter came on-line, Utah Paper Box has been a twofold increase in sheeted stock production. On average, the MSL sheets from 20 to 25 rolls of board stock during an 8-hr shift. Since service is a priority, this added capacity has helped to trim lead times. Boner adds, “Production-wise, the sheeter is no longer the limiting factor. It runs consistently with very little downtime.” He continues, “The Maxson sheeter plays an important role in a central core of our business. It has dovetailed quite nicely with our MAN Roland presses.”

With the necessary equipment in place, Utah Paper Box is ready to take on new business. The company plans to expand within existing markets, as well as capitalizing on opportunities as they develop. One area of recent growth has been the software industry. During 1991, sales reached a record $18 million, and business is on track for 1992. Thanks to Utah Paper Box’s quality commitment, success seems certain.

Reprinted from The Sheeting Monitor, June 1993