MAXSON AUTOMATIC MACHINERY COMPANY offers a roll decurl component that can be retrofitted to existing rotary sheeters to reduce curl related waste. The penetrating breaker roll decurl unit, mechanically flattens the incoming web caused by the roll set near the core. The resulting action ensures flat sheets at the sheeter’s pile.

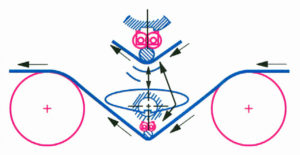

The penetrating breaker roll design employs a free-spinning breaker roll that is supported across the width of the assembly by back up bearings, which are mounted on a rigid cross member. In cases when the breaker roll is small, magnets are used to hold the steel rod in against its back up bearings. The breaker roll penetrates into the web against a king roll decurling the web.

The decurl assemblies can be designed to accommodate multiple webs, ranging from 40# – 0.040” thick (60 – 800 gsm) material. Each decurl station can be outfitted with various diameter breaker rolls that can flatten the web without damaging the surface of the material. Positioning the decurl penetration can be accomplished manually or automatically by the motorized controls provided.

The free-standing assemblies are designed to easily fit between the infeed of the sheeter and the roll stand area to minimize installation effort. Properly designed decurl units can reduce roll waste by up to 2% of total weight.