In the late 1870’s, a Cincinnatian named Sabin Robbins traveled throughout the South selling supplies to pharmacists. Since the paper bag had not been invented at that time, pharmacists rolled the goods in a sheet of paper and twisted the ends. Seeing an opportunity, Robbins struck a deal to buy over runs or “job lots” from Ohio paper mills and resell it to his customers. One day, a local printer ran out of paper. Remembering the sheets he had seen at the nearby pharmacy, he asked to use some. To the surprise of the printer, the quality of the paper was much better than he had been getting and less expensive too. By 1884, Sabin Robbins established a company bearing his name to sell “job lot” paper to printers.

John Brady, Sabin Robbins’ Vice President of Operations, relates the story of the Company’s entrepreneurial founding to illustrate how good ideas become great ideas. It’s a philosophy that has served Sabin Robbins well. Today, the employee owned company, with nearly 300 people, has 5 converting and distribution centers throughout the United States servicing the Printing and Packaging Industries.

John Brady, Sabin Robbins’ Vice President of Operations, relates the story of the Company’s entrepreneurial founding to illustrate how good ideas become great ideas. It’s a philosophy that has served Sabin Robbins well. Today, the employee owned company, with nearly 300 people, has 5 converting and distribution centers throughout the United States servicing the Printing and Packaging Industries.

Another example of a good idea was Sabin Robbins expanding into converting. For almost 90 years, Sabin Robbins relied on others to convert their inventoried paper stock to the Customer specified roll width or sheet size. “We actually didn’t get into sheeting until the early 1970’s”, Brady stated, “when the mills decided they didn’t want to sheet paper any more. Instead they wanted to sell just rolls. We needed to service our customers. Rather than relying on out side sources, we believed we could control costs and deliveries better doing it ourselves, so we began investing in converting machinery.”

In response to supporting their customers, Sabin Robbins established regional converting centers in Mansfield OH, Atlanta GA, Dallas TX, and Los Angeles CA. With the ability to sheet and deliver orders quickly from its converting facilities, the Company was able to consolidate its network of warehousing space across the country. Rapid response to clients and lower carrying costs for inventory ushered in a period of growth that has seen Sabin Robbins increase by more than 50% in the past six years.

Then as now, Sabin Robbins customer base was diverse, running the gamut from commercial printers, envelope manufacturers, folding carton operations and blister packaging companies. Today, the company maintains various grades of inventory from 30 lb paper to 0.024″ thick board. Being able to address such a wide range of products and meet ever tightening delivery schedules required a multiple sheeter operation.

For example, in the Mansfield OH facility, where David Matheny is the plant manager, five sheeters and two guillotine trimmers converted a wide range of orders from rolls to finished, press ready sheets. But recently even this capacity was inadequate. Matheny explains, “More than anything, we wanted to sheet rolls without having to trim to a finished size afterwards. To come up to the time frame the markets were demanding, we needed to deliver a custom sized sheet out to the Customer within three days. The older machines weren’t able to get the production out that we knew we could get out of a new, precision sheeter.”

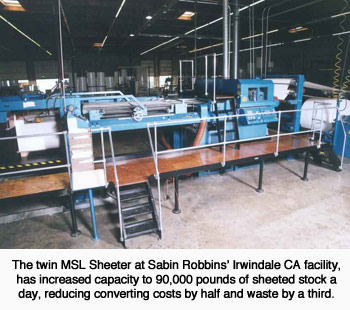

Likewise at the Irwindale CA facility outside of Los Angeles, three sheeters and two guillotine trimmers labored to keep up with the demands of service. Bill Woodhouse, the Western Regional Manager of the California facility concurs, “Our major niche is to be able to convert a sheet paper to a non standard size within a two or three day period. We need to be able to put a sheet of paper on their floor in a very short period of time.”

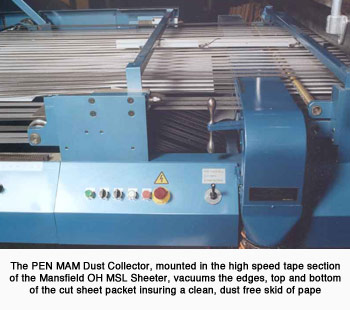

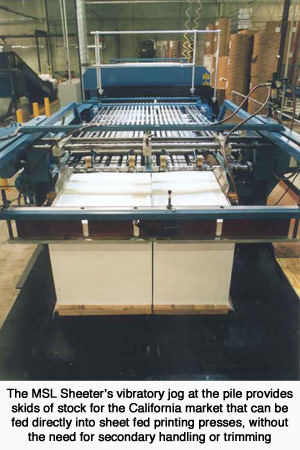

Management determined that the next investment in sheeting equipment would need to deliver a dust free, square, accurate sheet directly from the stacker. The Mansfield OH facility was selected to receive new equipment because it was the largest of Sabin Robbins’ four converting operations. It was determined that the California operation, owing to its more remote location and ability to take advantage of modern equipment would also benefit from a precision sheeter. Beyond that, as John Brady relates, ” We wanted a machine that could run light weight papers all the way up to board. Another factor was the speed the sheeter could run at, as well as the machine’s footprint. We didn’t intend to have a sheeter that took up a lot of space.”

Management determined that the next investment in sheeting equipment would need to deliver a dust free, square, accurate sheet directly from the stacker. The Mansfield OH facility was selected to receive new equipment because it was the largest of Sabin Robbins’ four converting operations. It was determined that the California operation, owing to its more remote location and ability to take advantage of modern equipment would also benefit from a precision sheeter. Beyond that, as John Brady relates, ” We wanted a machine that could run light weight papers all the way up to board. Another factor was the speed the sheeter could run at, as well as the machine’s footprint. We didn’t intend to have a sheeter that took up a lot of space.”

Sabin Robbins investigated several different manufacturers of sheeting equipment. According to Brady, “We spoke to companies that had sheeters. We knew of a California printer who had two Maxson sheeters”. Since they were satisfied with the machine’s capabilities for their demanding work, we knew MAXSON’s equipment could meet the Industry’s requirements. Beyond that, as a US manufacturer, we knew we could get parts quickly from Maxson if we needed them.”

For its Irwindale CA and Mansfield OH operations, Sabin Robbins elected to invest in the Maxson MSL Sheeter. Each 65″ wide sheeter was outfitted with shaftless roll stands, an electronic drive that governed sheet length, a dust collector to maintain dust free sheets, and the Maxson Airfoil Overlap.

With the shaftless roll stands; the MSL routinely sheets two rolls of 100# coated text and up to two webs of 80# cover grades. Because of the roll stands’ automatic tension control and the cutter’s dual motor drive, sheet length accuracies of + 0.015″ are maintained. Says Harvey Carroll, Irwindale’s plant manager, “The ability to enter the desired cut off by key pad entry, aids in quick set up times. The accuracy is great”. “We haven’t had a complaint associated with any orders sheeted on the Maxson”, adds Whitehouse.

Speaking about other features of the MSL Sheeter, Carroll continues, “The dust collector is definitely a great asset, insuring a clean sheet. The jam detectors mounted throughout the sheeter and safety features protecting the operators are big improvements over our existing sheeting equipment. The Airfoil helps to increase the speed on the lighter weight papers in the delivery system and it requires no adjustment.” “The quality of sheeted stock coming off the Maxson sheeter is comparable to that the mills are offering”, concludes Carroll.

Speaking about other features of the MSL Sheeter, Carroll continues, “The dust collector is definitely a great asset, insuring a clean sheet. The jam detectors mounted throughout the sheeter and safety features protecting the operators are big improvements over our existing sheeting equipment. The Airfoil helps to increase the speed on the lighter weight papers in the delivery system and it requires no adjustment.” “The quality of sheeted stock coming off the Maxson sheeter is comparable to that the mills are offering”, concludes Carroll.

There was a learning curve to address the new technology of a precision sheeter, but the issues centered on the attention to detail to insure finishing off the sheeter. “It was not a difficult transition”, reports Carroll. “And a few months later, Maxson field service paid a complimentary visit to us to review how the sheeter was running and to answer any questions the operators had. That was a real bonus.”

As in Ohio, the addition of the Maxson Sheeter in California has delivered benefits. Deliveries of non-standard sizes can be shipped within a couple of days without disrupting production schedules. The MSL also has provided the flexibility to convert surplus rolls into standard sheet sizes that can be shipped from Sabin Robbins inventory. Carroll notes, “With the Maxson, our overall production has increased by about 90,000 pounds a day.” Bill Woodhouse adds, “And it’s a big cost savings too. By eliminating the guillotine trimming step we reduce our converting labor costs by half.” “Based on our experience in the job lot business, the MSL Sheeter’s precision reduces waste by about a third over conventional sheeting.”

All of these benefits have added up to precision sheeting being a great idea for Sabin Robbins. By addressing the issue of quick deliveries for short run non-standard orders, Sabin Robbins has been able to provide its customers with better service. The Maxson Sheeters have allowed the Mansfield OH and Irwindale CA operations to realize faster turnarounds and improve the quality of its sheeted stock.

Sabin Robbins dedication to customer service has been instrumental in aiding the company toward total customer satisfaction. Its purchase of the MSL Sheeters is the latest step in that direction. This constant attention to quality and service can only continue to allow Sabin Robbins to remain a leader within the paper merchant industry where good ideas become great ideas.

Reprinted from Walden Mott Convention News, March 2003