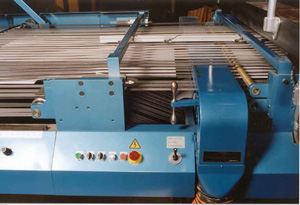

As the sheet packet is conveyed from the cutter to the piler, it passes between the two suction headers. At the point of application, ionized bars reduce static build up. The top, bottom and edges of the cut packet are vacuumed clean of loose fibers without contacting the sheets. The dust particles pass from the headers through the flexible hosing to a filtered dust box, which traps particles as small as 5 microns.

As the sheet packet is conveyed from the cutter to the piler, it passes between the two suction headers. At the point of application, ionized bars reduce static build up. The top, bottom and edges of the cut packet are vacuumed clean of loose fibers without contacting the sheets. The dust particles pass from the headers through the flexible hosing to a filtered dust box, which traps particles as small as 5 microns.

The suction headers have easily adjustable orifice openings, which allow the Operator to vary the suction flow from zero to thousands of cubic feet per minute. The ability to remove debris from the sheet after cutting, offers the benefit of cutting more webs at a time, thereby improving sheeter productivity.

Because of its compact design, the PEN MAM Dust Collector can be ordered as an original piece of equipment or as a retrofit to existing sheeters.

Please contact Brent H. Burdick, Director of Sales & Marketing, for further information by telephone at (401) 596-0162 or by e-mail at bburdick@maxsonautomatic.com.