Setting up an in-house sheeting operation to better control quality and turnaround time has worked out well for Salwen Paper, Edison, NJ. The company has enjoyed an 80% increase in solid bleached sulphate board sales since the company installed its first sheeter in 1983.

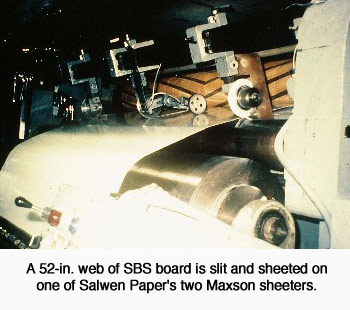

That unit, along with another purchased in 1985, has enabled 79-year-old Salwen to provide SBS customers in the Northeast with faster deliveries and a more consistent of the “middleman” converter. Both sheeters were supplied by Maxson Automatic Machinery.

Salwen Paper entered the SBS market in 1976 as a brokering SBS, Harry Salwen, president, realized that to provide higher quality, fast delivery, better service and a better price.

Scheduling problems with outside sheeters initially prompted Salwen to consider in-house sheeting. Local sheeting companies insisted that deliveries of SBS webs from Salwen arrive at specific times during the day or they would not be accepted. Salwen Paper was forced to comply with a schedule that was convenient for its suppliers, but always convenient for Salwen or its customers. Additionally, the company was limited it the amount of business it could take on, based on its sheet suppliers’ ability to handle orders and meet delivery dates.

Scheduling problems with outside sheeters initially prompted Salwen to consider in-house sheeting. Local sheeting companies insisted that deliveries of SBS webs from Salwen arrive at specific times during the day or they would not be accepted. Salwen Paper was forced to comply with a schedule that was convenient for its suppliers, but always convenient for Salwen or its customers. Additionally, the company was limited it the amount of business it could take on, based on its sheet suppliers’ ability to handle orders and meet delivery dates.

The primary consideration in selecting a sheeter was finding a machine that delivered a press-ready skid. Salwen Paper knew it would be competing with the same supplier it used in the past, and that meant its product had to be the cream of the crop.

The company investigated what other sheeting houses were supplying a quality product, and found out what equipment those firms were using. With the installation of its first sheeter in 1983, Salwen Paper entered the SBS market under full steam. Shortly thereafter, the company realized that the purchase of a second sheeter was only a matter of time.

According to Salwen’s specifications, each sheeter is customized to sheet a 22 to 78-in. cutoff length and is equipped with a shaftless self-loading back stand and a stacker. A separate back stand was later purchased to be used as a floater between the two units so Salwen could sheet multiple webs simultaneously for higher production.

The operation can sheet two superimposed 52-in. webs or two 26-in. webs side-by-side to accommodate what is in stock at a particular time.

Several features of the machine have been said to increase productivity and quality:

An airfoil overlap increases speed of stock flow through the delivery tape section by preventing jam-ups at the point of overlap.

An extending grid system at the stacker keeps production going during skid changes.

A dust collecting system at the delivery tape section suctions off dust through flexible hosing and collects in box with four individual filters. Salwen Paper also stretch wraps all of its pallets to ensure that dust will not interfere with print quality later on.

Sheet length accuracy of +/- 0.023 in. is said to be maintained at all times, even at top speeds to 1,200 fpm.

Salwen Paper attributes its rapid growth and success in sheeting SBS in large part to the accuracy and production levels its managed to achieve on the sheeters.

Reprinted from Boxboard Containers, February 1987