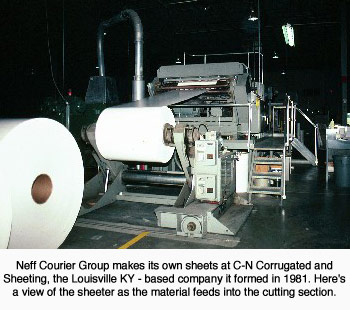

Rather than contend with the long lead time and accompanying production downtime of ordering sheeted board from outside sources, The Neff Courier Group created its own sheeting company,. The company, C-N Corrugated and Sheeting, was launched in 1981 to meet the group’s need for high-quality sheeted material with an extremely short lead time.

“We created C-N because we required sheeted material on very short notice. To meet this demand, we keep a large roll stock inventory of SBS and SUS board, and can usually turn an order around in a day or less,” says Matthew Klusmeier, president and chief operating officer of C-N.

C-N keeps more than 300 tons of roll stock in inventory for The Neff Courier Group and sheets on an “as needed” basis. This accounts for 95% of C-N’s business. The remaining five percent is for local lithographers. The company also cuts and scores corrugated sheets for folding into boxes and has a Kohmann windowing machine for creating windows or inserting adhesive backed supplements into folding cartons.

“Although our main operation is sheeting board for our parent company, the corrugated carton and windowing operations are an important segment of our business,” Klusmeier says.

Limited by technology

Unlike many other purchasing decisions, which sheeter to purchase turned out to be an easy choice for C-N. Before the Neff Folding Box Co. merged with the Courier Carton Co. to form The Neff Courier Group, Courier had an older Maxson sheeter operating in its plant. The Neff Courier Group originally moved that sheeter to C-N when it began. C-N found that although the older Maxson was still operating well, it was limited by the technology of its era-the early 1950s.

“We had a great deal of success with the older sheeter and we were very impressed with its durability. So, when we decided to upgrade our sheeting operation, we called on Maxson again,” Klusmeier says.

The Louisville, Ky.-based sheeting company utilizes a high quality precision sheeter from Maxson Automatic Co., Westerly, R.I. C-N runs the sheeter between 650 and 700 feet per minute and finds it accurate to +/- 0.023 inches.

“Speed and accuracy were the two main reasons we purchased a new sheeter. We wanted to assure the rapid service we’re known for,” Klusmeier says.

To obtain the most efficient sheeting possible, C-N also installed an options package on the Maxson MSL sheeter, which included a decurler, a self-loading shaftless back stand, a PEN-MAM dust collector, a continuous delivery system, a sheet length monitor and a trim slitter with removal system. The trim slitter installed on the sheeter has been especially helpful to the company by ensuring that the width of all sheets is consistent and square. “we ensure a perfectly square cut by first slitting the edges to compensate for any roll imperfections,” Klusmeier explains.

The optional package has significantly reduced changeover downtime of the company’s sheeting operation. Roll changes now take just a few minutes with the self-loading shaftless back stand, according to Klusmeier. The operator removes the core of the finished roll. He rolls a new roll in place and activates the back stand, which automatically grabs hold of the roll between chucks and lifts it into place. This allows him to thread the machine and resume production.

The optional package has significantly reduced changeover downtime of the company’s sheeting operation. Roll changes now take just a few minutes with the self-loading shaftless back stand, according to Klusmeier. The operator removes the core of the finished roll. He rolls a new roll in place and activates the back stand, which automatically grabs hold of the roll between chucks and lifts it into place. This allows him to thread the machine and resume production.

After the rolls are sheeted, the continuous delivery system also helps in reducing downtime by allowing production to continue when off-loading completed skids from the Maxson series 250 stacker. The extending grid mechanism of the system temporarily holds sheeted material while the operator off-loads the skid.

C-N utilizes the sheet length monitor when preparing the sheeter for a new cutoff, which further reduces waste and downtime. The monitor enables the operator to preset the sheet length and fully monitor the machine to ensure consistent, accurate results. The monitoring capability also allows the operator to check the linear footage of rolls on a regular basis.

Making room

The company is also in the process of expanding its existing facility to make more room for inventory. The 33% expansion will allow the company to store roll stock for both its parent company and outside business when needed. Klusmeier notes that the expansion is just the first step in the company’s effort to provide more efficient service.

“We’re always looking for ways to increase our service and efficiency. We are investigating the possibility of implementing a complete SPC program throughout the Neff Courier Group after this expansion is completed.”

Reprinted from Paperboard Packaging, April 1989