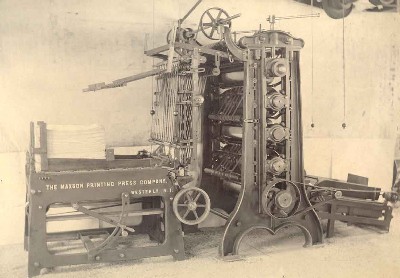

When he started his own engineering firm late in life, Charles B. (“C. B.”) Maxson was already an accomplished machinery designer with over a half dozen patents associated with sheet delivery systems for printing presses. In the early 1900’s, young children were employed in paper mills, as “lay boys” at the end of cutters to jog and pile sheets of paper. Maxson identified the potential of automating this process.

Collaborating with the Erie Machine Shops of Erie, Pennsylvania, Maxson formed the Erie Lay-Boy Company based in Westerly RI. Based on Maxson’s designs, Erie Lay-Boys were built in Pennsylvania then shipped to the customer’s site to be installed. Aided by his son Julian, Maxson’s Erie Lay-Boy outfitted rotary cutters with conveying and stacking systems throughout the Paper Industry. By 1920, Louis (“Lou”) L. Matthews was assisting with the engineering designs and installations of the Erie Automatic Lay-Boys.

In 1921, Maxson Automatic Machinery Company registered “MAMCO” as the company’s trademark. To this day, customers use MAMCO and Maxson interchangeably to identify the Company.

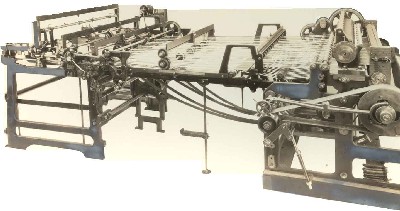

During the 1920s, C. B. created two concepts that would revolutionize sheeter design. In July 1925, the US Patent Office awarded Maxson the first of a series of patents for a sheet feeding and stacking method and machine that permitted sheets to be conveyed in a shingled, or overlapped, fashion. This overlapping delivery system allowed rotary cutters to run at two to three times the previous speed when sheets were conveyed from cutter to piler separated by a gap. As a result of this development, for over a generation, the Erie Overlapping Delivery was an integral part of most high production sheeters.

Following up on the overlapping delivery system, Maxson received patents beginning in December 1926 for a counting and marking machine. This design mechanically monitored the number of sheets cut and at a preset count, inserted a tag into the stack of paper. The benefit of the design was a dependable, accurate method of marking reams of sheets in the skid, thereby eliminating costly hand counting. C. B. Maxson originally invented today’s tag inserter.