Royal Envelope, which dates its origins to 1978 when its 10 employees supplied financial institutions with envelopes, has grown into a full service envelope manufacturer complete with printing capabilities. Now with 60 employees, the family owned business possesses the ability to produce up to 8 million envelopes a week. “The underlying reason for the company’s growth”, according to General Manager Matthew Pusatera, “is their commitment to do whatever it takes to satisfy the customer.”

It was this commitment that led Royal Envelope in 1995 to invest in a five color 40″ Heidelberg sheet fed printing press. Now nearly 70% of Royal’s sales volume is run through their printing department.

Although the majority of revenues are generated in producing standard envelopes, today Royal Envelope focuses on the direct mail market – specifically the ad envelope business. This segment of the market requires a higher end product of multi color specialty paper that is demanding in terms of quality and delivery. Using Customer supplied designs, Royal proofs the artwork, prints and makes the envelopes and then ships them to a mailing house. Performing the critical services in the process, Royal bears the responsibility of providing a quality product in a timely manner.

Fulfilling a customer’s satisfaction begins with securing sheeted stock, (70 lb coated paper is the most popular), purchased in sheeted form from paper suppliers or converted from rolls on an in house sheeter. After printing, the sheet stock passes to the cutting department where over 700 different type, style and size envelopes can be die cut to customer specification. Once the envelopes are cut to the required pattern, the order is scheduled on one of eight folders. The folding equipment is different to handle various sizes, diverse styles and assorted quantities. Some of the folders can apply printing in a flexographic manner or adhere a window to the envelope.

The Management determined that to enhance their company’s competitiveness in pursuing larger contracts and boosting profit margins overall, they needed to upgrade the sheeting equipment. “There were a few reasons for investing in a new sheeter”, Matthew Pusatera explains.

“First, most of the revenue goes through the Heidelberg and that press needs trimmed sheets. But because the existing sheeter was pre 1960’s vintage, it couldn’t produce press ready sheets unless we guillotine trimmed afterwards, which was costly in terms of waste and labor. As for the alternative, we were tired of buying sheeted stock for the press because it was a lot more expensive than buying rolls.”

“Another issue is that in the envelope business the standard sheet sizes (23″ x 35″, 25″ x 38″, and 28″ X 40″) are not suited for envelopes. Envelope layouts for die cutting are crazy, so our most common envelope sizes don’t lend themselves to the standard folio sizes. We wanted to be in a situation where we could stock rolls from our paper supplier that matched our layouts, sheet them to the right size, say 23″ x 29″, and have less paper waste. Not only would we be paying less per pound for paper but we would have less waste too.”

“Another issue is that in the envelope business the standard sheet sizes (23″ x 35″, 25″ x 38″, and 28″ X 40″) are not suited for envelopes. Envelope layouts for die cutting are crazy, so our most common envelope sizes don’t lend themselves to the standard folio sizes. We wanted to be in a situation where we could stock rolls from our paper supplier that matched our layouts, sheet them to the right size, say 23″ x 29″, and have less paper waste. Not only would we be paying less per pound for paper but we would have less waste too.”

“Floor space was a consideration too. The old sheeter had two different six roll stands assemblies and was wide enough to stack only one pile across the machine. The two assemblies allowed for one set of rolls to be preshafted using an overhead hoist while the other assembly was in use. With a new sheeter capable of doing two pile work and using two shaftless self loading roll stands, we figured we could pretty much meet the production of the older sheeter with the new sheeter and use less space.”

Having identified justification for upgrading their sheeting operation, the owners first investigated buying preowned machinery. “We explored buying used equipment four to five months before contacting sheeter manufacturers. We couldn’t find a late model sheeter that fit our needs, recalls Matt Pusatera.

Matt recounted the stages of the purchasing decision. “Once the decision was made to buy new equipment, we did our own research to identify three manufacturers. After receiving proposals, we went to see the sheeters in the field and made a point of talking to the operators that ran them. We considered price in our decision and most offers were competitively priced. But we also favored a machine that was manufactured in this country. We didn’t want to risk waiting for a replacement part to be shipped from overseas, because I can not afford to have the sheeter down.”

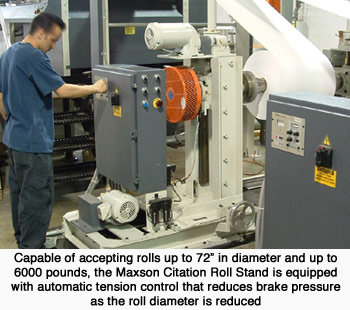

Royal Envelope purchased a MSP Sheeter from Maxson Automatic Machinery Company (Westerly RI). Outfitted with two shaftless self loading roll stands, it also included a slitter rig to allow 56½” webs to be slit and trimmed to two 28″ wide sheets across the sheeter. The cutter’s electronic drive maintains sheet length to within +0.015″ tolerance, providing press ready sheets. Royal Envelope chose an elevated stacker to match the maximum pile height of their printing press.

Royal Envelope purchased a MSP Sheeter from Maxson Automatic Machinery Company (Westerly RI). Outfitted with two shaftless self loading roll stands, it also included a slitter rig to allow 56½” webs to be slit and trimmed to two 28″ wide sheets across the sheeter. The cutter’s electronic drive maintains sheet length to within +0.015″ tolerance, providing press ready sheets. Royal Envelope chose an elevated stacker to match the maximum pile height of their printing press.

The installation was choreographed with the removal of the older sheeter. It took 2½ days to install the sheeter and another 2½ days to train the operators. Put into service in February 2004, the MSP Sheeter has satisfied its intended need.

The sheeter, manned by a single operator, runs two shifts a day. It consumes two 50″ diameter rolls of paper within 50 minutes, delivering skids of sheets that are fed right into the press. Sheeting related problems in the printing department are down markedly as the internal quality controls insure square, accurate sheets free of dust. Material purchases, which can account for upwards to 70% of a job’s cost have been slashed by 20%.

By replacing the older sheeter with the precision unit, Royal Envelope is poised to compete for business twice the size it has been accustom to securing. Further, with additional sheeting capacity available it is positioned to offer its converting services to local commercial printers. In that way, Royal Envelope prospers as they continue their commitment to do whatever it takes to satisfy the customer.

Reprinted from The Sheeting Monitor, January 2004