From a beginning six years ago in the basement of a home, a suburban Chicago, IL, envelope converter has grown steadily to become a successful operation with more than 70 employees.

Diamond Envelope, Naperville, IL, is a full-service envelope company serving a customer base concentrated along the East coast and in the Midwest. The firm’s niche lies in direct-mail pieces for financial institutions. Another growing segment of its business is the banding of greeting- and wedding-card envelopes.

Formerly located in Broadview, IL, the firm moved operations to a new 50,000-sq.-ft. facility in Naperville last month. The new facility provides Diamond Envelope with needed space for storage and warehousing.

During a period when markets have grown soft and competition has intensified, Diamond Envelope has secured a competitive edge by providing prompt service and a quality product.

During a period when markets have grown soft and competition has intensified, Diamond Envelope has secured a competitive edge by providing prompt service and a quality product.

“Service is the key in our business.” Alan Jania, who set up shop in the basement of his home in 1984, said. “The company that can get it done the quickest gets the order.”

The need to service orders quickly prompted Jania to consider in-house sheeting. Because Diamond Envelope was dependent on an outside source to supply sheeted stock, availability became a limiting factor.

At times, deliveries of sheeted stock could take from four to six weeks. In contrast, deliveries of roll stock took one week. “The mill’s time element bogged us down,” Jania said.

Diamond Envelope’s business had grown to the point where sheeting in-house made good economic sense. By purchasing a sheeter, the firm could avoid paying the mill’s up-charge for sheeted stock. ” By setting up our own sheeting operation, we could determine our own destiny.”

After investigating several sheeter designs, Jania selected the MSS-HS sheeter from Maxson Automatic Machinery, Westerly, RI. “Maxson’s reputation in the envelope industry was a deciding factor,” Jania said.” Because Diamond Envelope is family owned, we liked dealing with a family-owned company.”

The MSS-HS handles up to four rolls of envelope stock and operates at speeds up to 600 fpm. At Diamond Envelope, the new sheeter is operated on two shifts per day on six days per week. The sheeter requires only a single operator, and an average of 80,000 lb. of paper are sheeted each week.

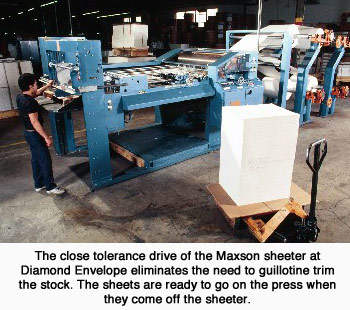

The sheeter has a close-tolerance drive that eliminates the need to guillotine trim. “The sheets come off the Maxson press ready,” Jania said. “Before the sheeter was installed, we had to pay for trimming, and now we don’t. Now, we can pass the savings along to the customer through lower prices.”

The sheeter has a close-tolerance drive that eliminates the need to guillotine trim. “The sheets come off the Maxson press ready,” Jania said. “Before the sheeter was installed, we had to pay for trimming, and now we don’t. Now, we can pass the savings along to the customer through lower prices.”

Waste is kept to a minimum with a sheet-length monitor that allows the operator to set the sheet length before threading the web into the cutter. When the sheeter is in operation, the monitor displays the sheet length to the nearest hundredth of an inch.

The benefits of sheeting in-house has been twofold. Since making the switch to roll stock, Jania estimates an annual savings of $70,000 to $75,000 in purchasing rolls versus sheets. “In total, our operating costs are lower,” Jania said. “In addition, we now have the ability to tap into any mill source for roll stock.” The production capacity of the sheeter has allowed the firm to turn orders around more quickly, according to Jania.

The decision to move to a new facility coupled with the purchase of a precision sheeter are two examples of how Diamond Envelope continues to seek new opportunities while planning for future growth. Jania’s challenge is to manage this growth effectively.

“Our goal is to tap into our existing customer base and grow from within, keeping in mind that service is why we’re here,” Jania said.

Reprinted from Paper Film Foil Converter, August 1990