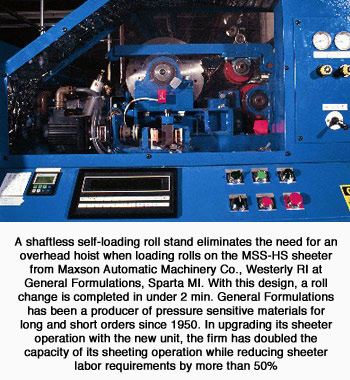

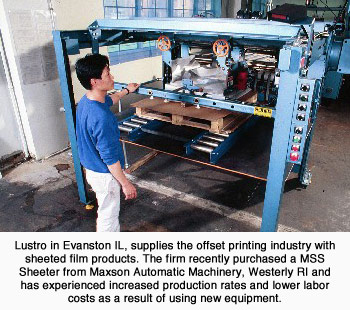

Lakeland Paper Company, located in Sturgis, MI is one trade converter with a formula for success. Much of this success lies in the company’s commitment to service and quality. As Charles Schmidt, Lakeland Paper’s sales manager, explains, “During the paper shortage of the early 1970’s, many small folding carton companies needed a source for sheeted […]