There was a time when little attention was paid to the needs of the developmentally disabled in our communities. Indeed, sometimes there was shame attached to admitting that a member of the family was so afflicted, and many individuals spent their lives in overcrowded, locked institutions, under-stimulated, bored and over-medicated. Those days are over, and a Maxson sheeter is a part of changes for the better.

Today, many programs, organizations, agencies and countless volunteers ensure a brighter future for people with developmental challenges. One such organization is the Advocacy and Resource Center (ARC) in Plattsburgh, New York. This not-for-profit agency was founded in 1954 by a group of determined parents who wanted to improve the quality of life for their children. Their goal was to obtain services for their children with special needs. Today, the agency serves over 500 men and women with developmental disabilities and their families. It employs over 350 personnel, having doubled in size in the last ten years.

Programs now available at ARC include Residential Services that provide environments for independent living geared to a range of capabilities. There are services that assist families with support, and the Merritt Memorial Center provides Habilitation services, pre-vocational training and Senior’s Programs. Many of these programs are the training grounds for teaching life and employment skills to those capable of taking on the challenges of work. Champlain Valley Industries is one such place.

Programs now available at ARC include Residential Services that provide environments for independent living geared to a range of capabilities. There are services that assist families with support, and the Merritt Memorial Center provides Habilitation services, pre-vocational training and Senior’s Programs. Many of these programs are the training grounds for teaching life and employment skills to those capable of taking on the challenges of work. Champlain Valley Industries is one such place.

Champlain Valley Industries is a place for stretching-the-wings and applying newly learned skills. It is a Sheltered Work Center within the Advocacy Resource Center with a variety of training programs. They include a self-funded janitorial service; an FDA-approved clean room where everything from inhalers to sanitary pads are assembled, packaged and shipped to New York State Government offices, prisons, state Universities, and tax departments. Workers at CVI even assemble light fixture ballasts for the New York City Transit Authority.

Scott Henderson, Director of CVI, is always looking for new opportunities to put hands to work. “The State of New York posts outstanding contracts on-line. We have an opportunity to bid just like anybody else,” he says. “I saw many contracts for various types of paper that would be supplied to various agencies of the State of New York. That looked promising and I decided to research that further.” Thus began Henderson’s initiation into the world of Maxson Sheeters.

After doing some homework, Henderson decided that sheeting paper was the way to take advantage of these contract opportunities. A consultant recommended that he approach Maxson Automatic Machinery Company for advice on what type of machine he would need to run five sizes, three weights and two finishes. A customized sheeter was designed to CVI’s specifications to make CVI competitive in the bidding. The design is so flexible that the desired five sizes have expanded to seven sizes and it includes a 12″ X 18″ digital paper size as well. Maxson made a deliberate effort to remove automated features of the machine and some options that would make it more labor intensive to operate. This would allow CVI to employ several individuals with differing abilities in a technical environment.

The New York State Industries for the Disabled granted CVI a one year contract with annual renewable options to sheet printing paper for the State. “This contract will help CVI provide consistent work for people with disabilities, which is not always available in commercial contracts,” said Henderson. “Especially significant is that this is just one of several contracts which CVI is now looking to bid on, all of which will strengthen our ability to provide increasingly technical jobs for our employees.”

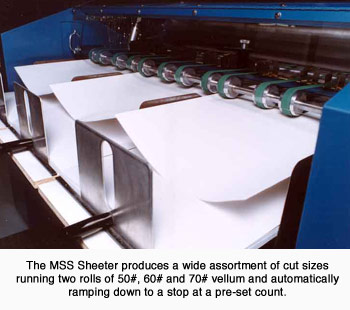

Henderson made the decision. Maxson Automatic Machinery Company. would supply a MSS specialty sheeter equipped with two shafted roll stands, a sheet-length monitor, slitters, and jogger table. The sheet-length monitor allows the operator to reduce cut-off changeover time and eliminate set-up waste. The jogger table efficiently places paper into reams and a counter automatically ramps down production to a stop at 500 pieces. The reams are manually removed from the jogger and either wrapped or placed in boxes in preparation for shipping. “Unloading takes less than one minute,” reported Henderson.

The roll stands can handle rolls up to 57″ wide, and are equipped with air brakes. The brakes are eased or applied according to a laser sensor which tracks how much paper is on the roll. CVI is sheeting two rolls of 50#, 60# and 70# vellum and long-grain, in an assortment of sizes that satisfy their contract with the State. Simple adjustment of the slitter positions and corresponding adjustments at the jog boxes accommodate both width and length changes. Cutoff length changes take less than two minutes and are as simple as a touch on a keypad control.

“We have been completely pleased with the Maxson sheeter. We got great advice about layout for maximum production and excellent training. We are seeing exceptional, dust-free product and the sheeter is surprisingly quiet,” comments Henderson. Because there was some parental concern about safety, a committee of parents and Advocacy employees visited the Maxson manufacturing facility in Rhode Island to examine the machine and see it operate. After scrutinizing the safety features of the MSS specialty sheeter, this very critical committee pronounced the machine safe for operation at CVI.

This sheeting system provides CVI with the potential to successfully compete in the market place while providing a highly technical training opportunity for the disabled of Clinton County, New York. Because CVI is non-profit and must remain so, all revenue realized by the sheeting operation is poured back into the agency to provide additional residential services and to cover agency expenses. This organization is truly self-sustaining. Its leaders demonstrate remarkable innovation and forethought in realizing the potential of those in their care.

Reprinted from The Sheeting Monitor, June 2000